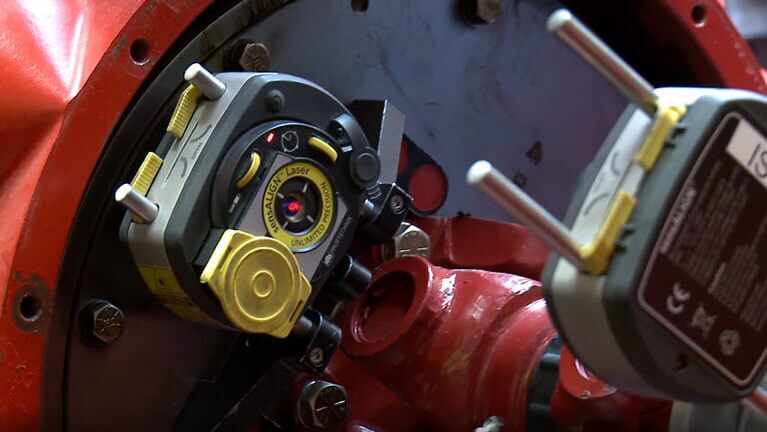

Fluke 831 Laser Shaft Alignment

Today’s maintenance departments can’t afford crippling unplanned downtime and wasted energy. You could be losing thousands of dollars per year in replacement bearings and hours of unnecessary repair time. Up to 50% of damage to rotating machinery is directly related to misalignment–most customers ignore it and simply replace the bearings and seals. See the benefits…