Improve Predictive Maintenance With Thermal Monitoring

No matter the industry or facility, responding faster to sudden degradation of an asset reduces potential failure, curtailing damage costs. During the last decade, maintenance managers relied more on thermal imaging for preventive maintenance and troubleshooting in manufacturing processes. Heat is often an early indicator of degradation, and cold spots often suggest blown fuses or failed capacitors. Therefore, identifying abnormal thermal patterns before a failure can extend asset life.

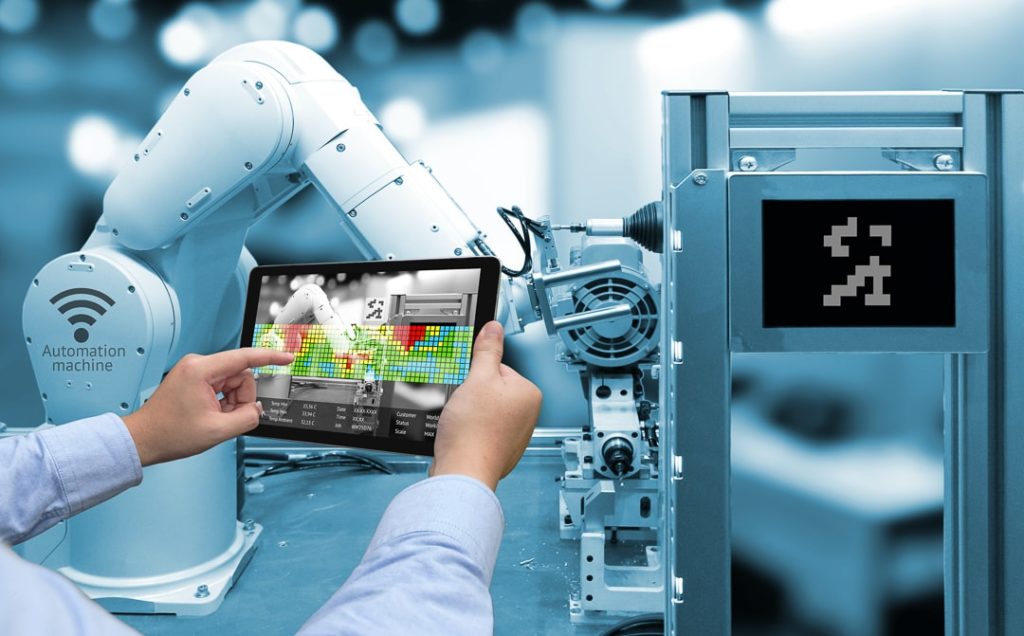

Professionals quickly identify hot or cold spots that indicate potential problems using thermal imagers — also called infrared cameras. Using condition monitoring tools and sensors helps avoid unexpected downtime and equipment damage. Maintenance technicians can inspect an entire area or a piece of equipment using thermal imaging. As anomalies are identified, the technician zeroes in on irregular areas to determine the magnitude of the problem.

Multiplying Thermal Imaging Capabilities

Recent generations of thermal imagers greatly improve the ability to catch many potential breakdown-causing problems before they cause a failure. The enhanced capabilities decrease costs and dramatically improved ease of use. Maintenance personnel would rather find an impending problem than have to respond to a critical equipment failure after it happens.

Facility managers, upon seeing the capabilities, are expanding their condition monitoring programs to include semi-fixed, always-on wireless infrared sensors. Previously, a technician had to be in the right place at the right time to troubleshoot intermittent problems. However, installing thermal imaging sensors on multiple components provides a more comprehensive view of equipment assets in real-time. Views also show long periods of time, making them much more likely to catch intermittent faults in the act.

Thermal imaging sensors simultaneously capture thermal images of multiple motor, fan, pump, and conveyor components to help spot abnormal thermal patterns in bearings, shafts, casings, belts, gearboxes, and other components. Managers can compare these images across an entire duty cycle to see what else is going on when warning signals appear. They can then respond proactively to problems and head off potential failures in other equipment down the line. The sensors provide more data to help maintenance and reliability professionals better determine whether they need to address the problem immediately or whether they can wait for off-peak hours or until the next regularly scheduled maintenance period.

How Thermal Imaging Sensors Work

Semi-fixed sensors operate on battery or alternating-current (AC) power. Sensors can easily be installed and moved to monitor the thermal profile of different components across extended periods of time. Technicians mount sensors on almost any surface, using magnets or adhesive discs. Additionally, teams can mount sensors with an adjustable, 360-degree bracket. The bracket allows positioning at many angles, capturing targets that would be hard to reach with a handheld camera. For optimal results, the sensors should be mounted at a distance of 4 to 20 feet from the asset. Users can set temperature thresholds for each sensor that triggers alarms if those thresholds are exceeded.

Each thermal monitoring sensor captures sequences of infrared images at intervals the technician specifies. Typically, it works best to start by taking images at frequent intervals to identify how quickly surface temperatures change. Then technicians can adjust the frequency to suit specific monitoring needs. For example, you might start with one image per minute. After that, if the surface temperature changes very slowly, you can change the setting to one image every 30 minutes.

Because all images in the sequence are captured from the exact same location, the angle and distance are identical. Using software on a mobile device or PC, end users can compare multiple images of the same asset or images of multiple assets taken simultaneously so hot and cold spots stand out. This provides a more complete picture of where problems are brewing and how thermal anomalies in one component are affecting other production assets.

The sensors operate for up to 10 hours on one battery-powered charge in high-performance mode. Similarly, sensors operate for up to three days in battery-powered, energy-saving mode. With AC power, there is no time limit.

Key Advantages of Semi-fixed Thermal Imaging Sensors:

- Troubleshooting: The sensors automatically capture a series of thermal images over an extended period of time. This allows maintenance technicians to view the results from any connected device. They make spotting abnormalities that develop over time easier.

- Versatility: Sensors are easy to install and move. Condition monitoring sensors mount on almost any surface.

- Data correlation: Manager and technicians receive alarms from connected CM software. Alarms are sent based on pre-determined thresholds. Software remotely monitors multiple assets and creates multiple graphs per asset, correlating thermal readings with other measurements.

- Portability: The sensors can operate on battery power for up to 10 hours in high-performance mode, three days in energy saving mode, and indefinitely if connected to AC power. This allows technicians and managers to monitor thermal readings out of harm’s way.

View and Analyze Results from Anywhere

Wireless thermal imaging sensors send the captured images to the cloud, using point-to-point Bluetooth or Wi-Fi connectivity. Technicians don’t have to run cables to connect with the local area network. A smartphone app then transfers data by cellular signal or Wi-Fi connection to secure cloud storage. Condition monitoring software manages the entire process. The software then provides reporting and graphing capabilities, and the ability to save images and measurements to work orders. Maintenance teams using CM software are establishing a reliable, traceable asset history.

Fluke thermal monitoring sensors, along with other Fluke products, seamlessly integrate with eMaint CMMS software. Whether measurements come from a sensor or a technician with a handheld meter or infrared camera, the software automatically saves the data and uploads it to the cloud. From there, end users can correlate other measurements taken by different devices (handheld or semi-fixed) to identify equipment issues. For example, excess heat may indicate a current spike in a motor or pump. Taking current measurements simultaneously with thermal images can provide a more comprehensive picture of overall equipment health. End users can then associate the measurements to equipment, build hierarchies and track historical trends in the software.

Putting Thermal Imaging Sensors to Work

When teams combine thermal monitoring with other condition monitoring sensors, they can troubleshoot more reliable. In turn, this improves the reliability-centered maintenance of assets in the manufacturing process, including:

- Motors, pumps, drives and compressors: Thermal imaging is particularly helpful when monitoring rotating equipment because overheating accompanies many impending failures. Technicians compare surface temperatures and quickly isolate failing (overheated) motors by installing sensors on multiple motors in a row. Teams repair or replace suspect components before they cause unexpected downtime.

- Process instrumentation: Valves, pipes and hoses are critical to delivering fluids to processes at precise moments. Thermal imaging sensors can help locate leaks, stiction or excess friction in valves and tubes. Proactive thermal monitoring of pipes can help locate obstructions before an entire loop fails. Thermal monitoring monitors liquid levels and conducts rough checks of dry bulk material levels in tanks.

- HVAC systems and condensers: In data centers, cooling is key to keeping servers from overheating. Sensors monitor server racks or heating, ventilation and air conditioning (HVAC) valves and condensers that are indoors. They can also identify uncharacteristically cool surfaces that might indicate a problem, such as an imbalance in the HVAC system.

- Small transformers: Thermal monitoring can quickly identify bad electrical connections, uneven or inadequate power supply, overloads, harmonics and other conditions that precede impending electrical equipment failures.

- Pre-commissioning tests: Technicians need to run mechanical, electrical and visual tests on a new transformer before it can be commissioned in the field. The combination of condition monitoring software and sensors for thermal imaging, voltage, current and contact temperature, can confirm that the transformer is operating properly and establish baseline data for future inspections.

Enhancing Preventive Maintenance with Wireless Infrared Monitoring

The flexibility, performance, and portability of thermal monitoring sensors can have a major positive impact on a facility’s reliability, efficiency, and performance in multiple ways.

Move from a reactive to a proactive mindset

Most facilities house seemingly countless components, from rotating assets to small transformers. Chasing problems as they surface puts a strain on even the most capable of maintenance teams, making it a challenge to try to get ahead of the wave. If the maintenance staff is spread thin and is constantly hustling to handle the latest equipment failure, response time can suffer.

As noted, warning signs, such as a significant rise or drop in operating temperature, precede most equipment failures. Thermal imaging sensors and condition monitoring software can help maintenance staff recognize the indicators that may lead to downtime if left unchecked. This helps maintenance managers make better decisions about maintenance schedules, work orders and prioritize situations that demand an urgent response.

Increase Efficiency and Maximize Human Resources

Smaller maintenance teams often outsource thermal imaging functions. Technicians who aren’t trained in regular inspections using tools don’t provide repeatable results. Therefore, leveraging simple-to-install and use thermal imaging sensors provides teams with quick measurements from their mobile devices. For instance, managers are replacing some inspection rounds with automated image collection using thermal sensors. A thermal sensor covers more ground than technicians, without having to increase overhead.

In other words, technicians are available to fix more equipment. Organizations can trust a sensor’s precision, developing a better idea of the overall health of a facility’s equipment.

Safely Inspect Hard-to-Reach Assets

In addition, thermal imaging sensors are non-invasive. Technicians can install sensors while assets are operating. Positioning sensors at different angles provides views into enclosures or difficult-to-reach locations. Using sensors, teams find problems in areas that are too difficult to access. Workplace safety is vital.

After technicians install sensors, measurements are available on their mobile device from anywhere, around the clock. The sensors present minimal safety risks (except for live voltage, which still requires full electrical safety precautions).

Storing sequential thermal images and other measurements on the cloud creates a rich equipment history that is easily accessed through mobile devices or PCs. Having this data close at hand saves time in searching for baseline measurements and enables maintenance managers to conduct smarter evaluations.

By helping maintenance teams detect a multitude of potential issues before they cause failures, wireless thermal imaging and other condition monitoring sensors in concert with a comprehensive condition monitoring software solution can make predictive maintenance even more predictable.

If you’d like more information on condition monitoring programs, please sign up to speak with our Customer Success Managers.