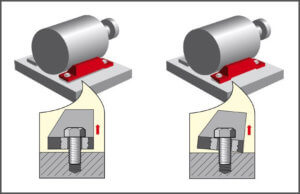

Give Soft Foot the Boot – Discover the Hard Facts

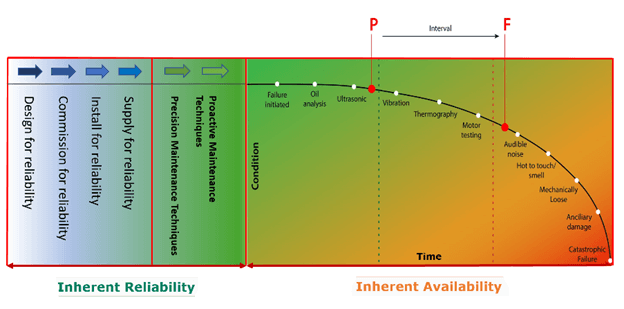

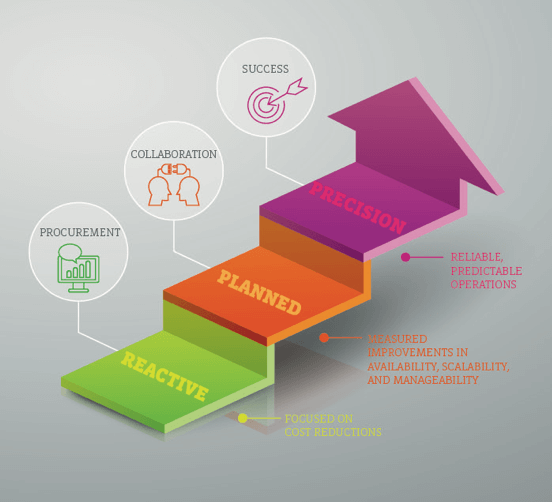

In this session, we explored the often-overlooked issue of soft foot—an alignment problem that can cause excessive wear, inefficiencies, and costly equipment failures. Our experts covered how to identify soft foot, why it matters, and the significant impact it can have on asset reliability. Learn practical strategies for detecting, preventing, and correcting soft foot using…