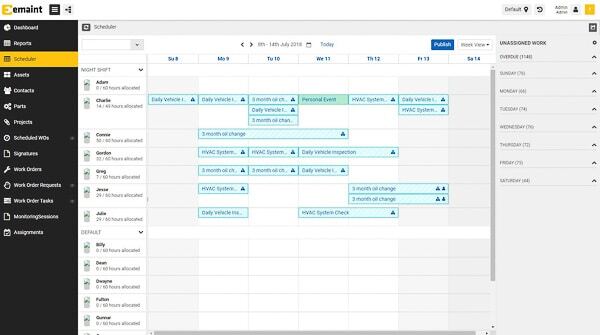

Practical Creation and Use of the Planned Maintenance Schedule

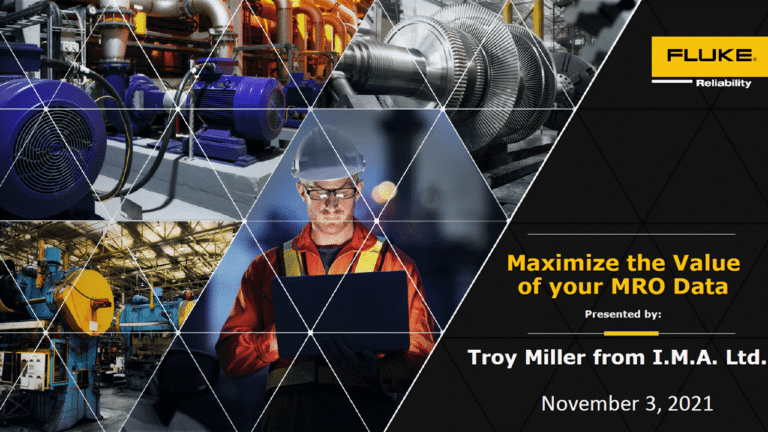

We as Asset Management professionals are always spouting off about Planning and Scheduling. However, where the rubber meets the road is an agreed-to and locked in weekly schedule by Operations and Maintenance that actually gets to the people who execute it, the technicians. This presentation will show how planned maintenance work gets to a schedule…