The exponential power of daily improvement

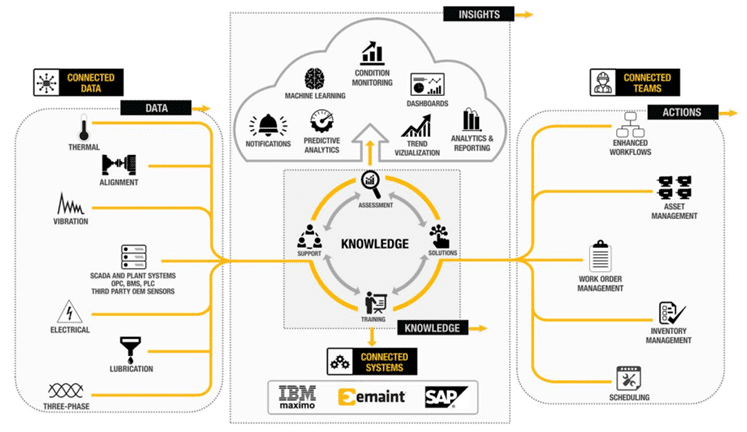

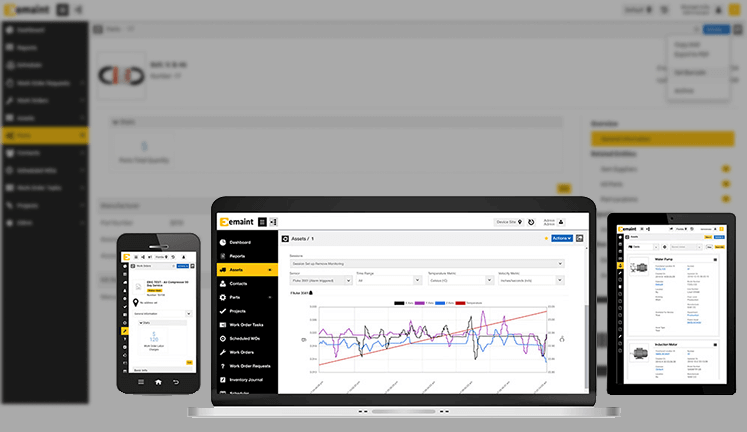

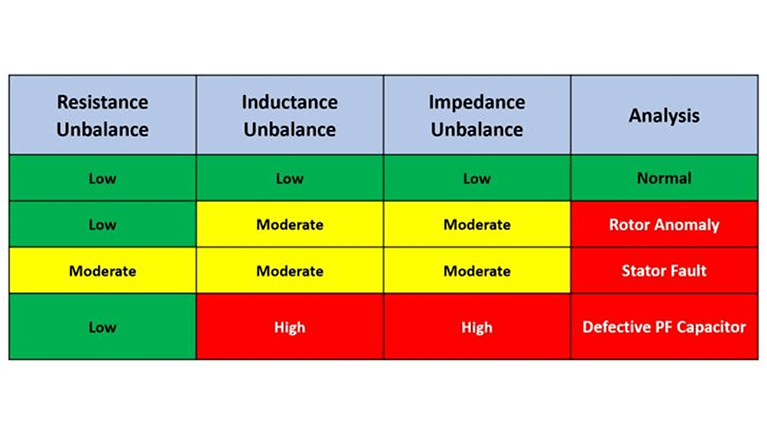

Calvin Williams has helped numerous companies build continuous improvement programs. In this webinar, he discusses the science behind daily improvement and how to use it to create a sustainable culture of continuous improvement. He relates how a 1% improvement daily amounts to 38 times better results in one year. He’ll also describe the power of…