Get more value from your CMMS (Part II): Integrations for improving machine health

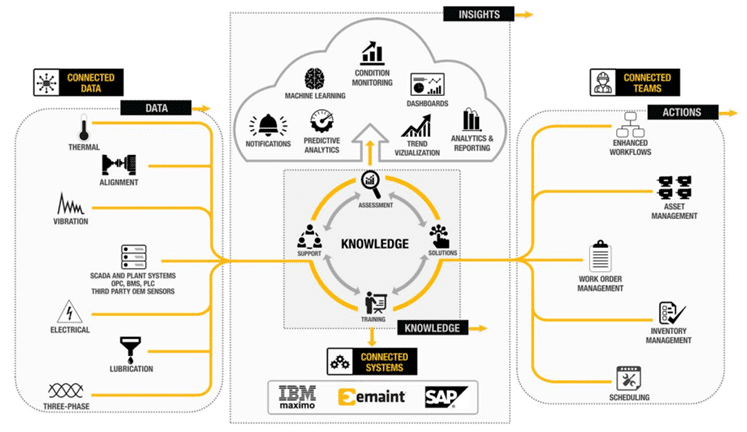

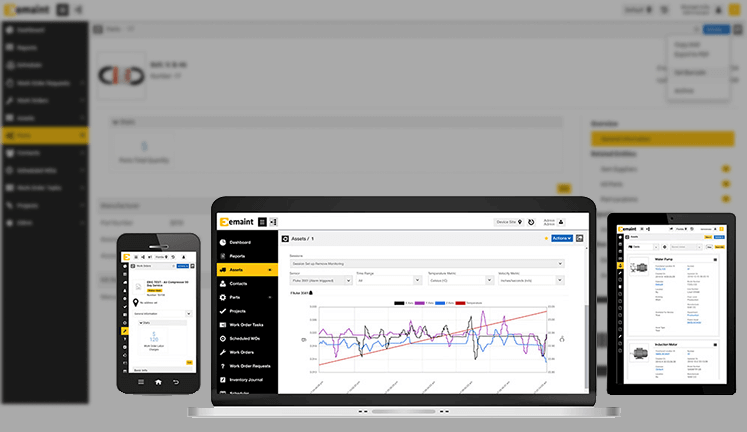

You may be surprised by how supercharged your CMMS can be when connected to more powerful sensors, software, and other compatible systems. Your CMMS is designed to support maintenance and reliability, and the outcomes only get better with systems that interoperate. Integrations can be painless and can set your company up for years to come….