Step up to improve your data quality and watch the confidence in your operations grow

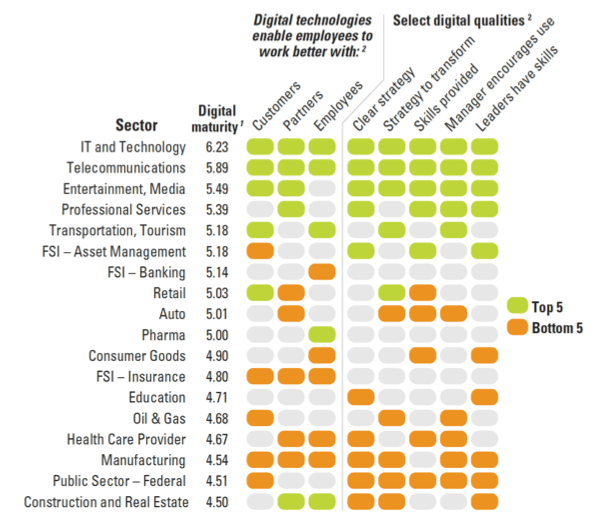

A recent study published by MIT Review suggests that the manufacturing sector is making life harder than it needs to be. Manufacturing ranks among the bottom five sectors to be using digital technologies to enable employees to work better.

Manufacturing has digitalized many of its systems, but it hasn’t managed to achieve the transformative results of other sectors, where digitalization is often done according to a clear strategy and is accompanied by training and management support.

Why does that matter?

In the words of Kevin Clark, CMRP, “Data enriches a technician’s experience and performance.” In April 2020, Clark and Matt Midas, the Vice President for Performance Management at Cohesive Solutions, Inc., co-presented at a webinar titled, “How to ensure quality data drives your maintenance practices.”

Access to quality data is important in manufacturing (and elsewhere) because this is the information used in operations, decision making, and planning. If the data isn’t highly reliable – if it doesn’t accurately represent the real world – then the operational actions, planning, and decisions supported by it will go awry. As some would say, “Garbage in; garbage out.” More likely, teams will ignore or develop workarounds to the untrustworthy data, making it even harder to manage processes or track asset health status.

By implying that manufacturing hasn’t digitalized effectively, the MIT Review study is effectively saying that manufacturers’ data isn’t of enough quality to be useful to employees. Compounding the issue, the industry’s data is also usually siloed – stored in multiple different systems, on multiple screens, and not always accessible when and where it needs to be.

What’s interesting is that better technology isn’t always the direct fix to the problem. Midas references other findings from MIT Review that show that process changes have a much bigger impact. New technology can alter processes, which changes the way people perform their tasks and define their roles. But it’s those role changes that actually drive measurable improvement in the metrics.

By improving data quality, you can improve data confidence, and that confidence is what translates to better decisions, increased efficiency, and greater team alignment.

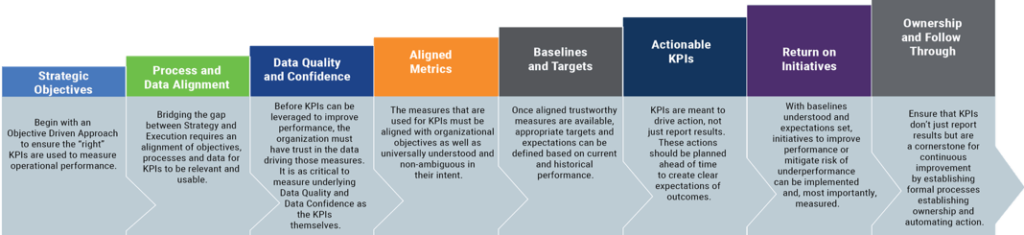

Midas has concrete suggestions for how to ensure quality data is driving your maintenance practices:

- Stated goals and objectives

- Clearly defined processes

- Process and data alignment

- Data strategy to drive quality and confidence

- Aligned metrics

- Baselines and targets

- Actionable KPIs

- Follow through

Listen to the full webinar to hear how Midas explains each of these recommendations.

Both Midas and Clark agree that there is a role for technology in the journey to increase data quality, and the latter part of the webinar features some strategic advice on “what good looks like.” In other words, any number of tools you can help you collect, manage, share, and report data, but you must lead with an objective and a strategy for that data in order to achieve satisfying results. Start with the end in mind.

Also, remember that modernizing data can be tricky. “People’s views on data quality can often be in disagreement, even when discussing the same set of data used for the same purpose,” says Clark. Midas lists a number of common challenges to data quality improvement and offers advice on how to overcome them. Their joint presentation closes with thoughts on process and performance management, dashboards, and how to know if you’ve got good data.

You can access a recording of the full webinar at Accelix.com.