LORA (Level of Repair Analysis) may be the smartest way to maximize your asset maintenance ROI

Lucas Marino, veteran military engineer and an expert on LORA, explains its benefits in a recent webinar

While the U.S. Military documents its operations thoroughly, many outdated processes still exist because “that’s the way it’s done.”

In his nearly 20 years of experience maintaining military ships and landing craft, reliability expert Lucas Marino has discovered many such instances of “tribal knowledge.” It was while digging into the economics of asset life cycle management that Marino uncovered the most significant process gap of all. An oversight in Coast Guard cutter maintenance was causing substantial inadvertent cost overruns. His identification and study of the missing link eventually drove him to champion a transformational process called LORA, or Level of Repair Analysis.

Level of Repair Analysis (LORA) is a decades-old strategy of asset management that examines not just the level of criticality of an asset but the business case around its upkeep. You can think of it as a decision-making logic that drives what level of maintenance is applied to various assets.

LORA doesn’t just work in the military; its benefits span industries of all kinds. The goal under LORA is to “right-size” total maintenance allocation, where “right” is ultimately situational (level of risk, asset mix, labor mix, production goals), and “size” has a lot to do with overall expense. The process is an excellent exercise in maximizing return-on-investment (ROI).

Marino discussed the strategies and thinking behind LORA at an August 2019 webinar as part of the Accelix Webinar Series. To view the recorded presentation, visit this page.

While the military is famous for being able to double the lifespan of its assets, not every asset deserves that degree of maintenance, and nor should you bring in the best team for every job, Marino notes in his presentation.

But how do you create a repeatable decision-making process for determining the appropriate lifespan and resource allocation across assets and facilities of all sizes? That’s where LORA, integrated with a business case analysis, comes in.

The rationale behind LORA

Here’s the U.S. Coast Guard’s definition of LORA:

“An analytical methodology used to determine where an item will be replaced, repaired, or discarded based on cost considerations, unit maintenance capabilities, and operational readiness requirements.”

The three key elements to LORA are cost, risk, and performance. In other words, what is the cost of the asset and the labor, what is the risk of asset failure, and what level of asset performance is desired.

After all, as Marino says, “You need efficiencies and effectiveness to maximize productivity and your ROI.”

Framework for applying LORA

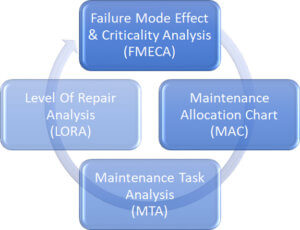

The LORA sits on top of several supporting elements, including:

- Failure mode effect and critical analysis (FMECA)

A hallmark of reliability maintenance, FMECA is a method for analyzing manufacturing processes, identifying probable or actual points of failure (failure modes), and assessing the impact of that failure (criticality) - Maintenance allocation charts (MAC)

Primarily a task-assignment tool, the MAC designates overall authority and responsibility for the performance of maintenance functions - Maintenance task analysis (MTA)

An MTA breaks down the tasks, materials, skills, infrastructure, and time required to maintain and repair an asset or asset component

Logistics engineering analyses

These three analyses provide the necessary level of data about the asset and the facility to determine what level of repair an asset should receive. If your facility isn’t already performing these processes, it may not be ready for LORA.

How it works

LORA is performed in four steps, each described below:

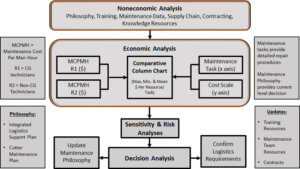

- Non-economic analysis

- Economic analysis

- Sensitivity analysis

- Decision analysis

Step one is a situational analysis. It asks questions such as, what level of skill and training does the on-site team have, and what degree of maintenance are they able to conduct without external support? How sensitive is the supply chain, and how fast or slow are replacement parts?

Step two compiles the hard costs of maintenance, including the cost per man hour of on-site and consultant labor, the time it takes each type of labor to complete a task, and at what total cost.

Step three assesses the criticality of the repair, the level of risk associated with asset failure, and the level of cost incurred by over-maintenance.

Step four triangulates asset health goals against the various levels of repair so that it becomes clear what degree of maintenance expense best supports the organization’s budget and desired level of uptime.

Asset managers then fold the results of the analysis into their maintenance planning, with the goal of building an effective maintenance support structure.

Marino developed this model to guide practitioners through the LORA steps

Understanding what these four steps are and how they work together was the big “Ah-hah” moment of Marino’s research. By quantifying and eventually monetizing these aspects, he was able to create a repeatable model to guide decision making.

To be successful, level of repair analysis requires executive or management sponsorship. That’s because the analysis itself takes time, and the resulting recommendations often require long-term thinking to be successful. LORA is a strategic approach to maintenance and management that potentially affects millions of dollars’ worth of assets and equipment.

Marino’s webinar presentation includes a compelling case study regarding vessel maintenance within the U.S. Coast Guard, where he served 19 years as an officer and engineering leader. He is currently publishing a book, due out by 2020, with extensive guidelines for asset lifecycle management. For more information regarding LORA as well as his new book, visit this website.

Related articles

7 benefits to help make the case for Asset Criticality Assessment

How power monitoring can save your budget and business

Webinar: How Industry 4.0 and IIoT drive a new world of maintenance