Maintenance planning do’s and don’ts to increase your M&R team’s effectiveness

Those responsible for reliability maintenance and asset uptime should consider adding maintenance planning to your list of critical processes. That’s a major takeaway from a Fluke Reliability Best Practice Webinar in April 2020 in which reliability expert Shon Isenhour scrutinized the quality of today’s maintenance planning practices.

Isenhour, a founding partner of asset management consultant Eruditio, surveyed industry practitioners over the previous year and found that only 3% felt their company did a good job at maintenance planning. That low number was so shocking that he put together the webinar presentation, “So your planner doesn’t plan? How to move away from unplanned maintenance.” You can listen to the on-demand version of the webinar on Accelix.com.

“We are really missing a huge opportunity to make a step-change in reliability,” simply by not adhering to best practices in maintenance planning, Isenhour said.

“Lack of planning significantly reduces the effectiveness of maintenance and reliability. A lot of really good sites could be a lot better if they could focus on planning and scheduling.” Start by understanding what maintenance planning truly is, and then look at where to make changes and improvements, he urged.

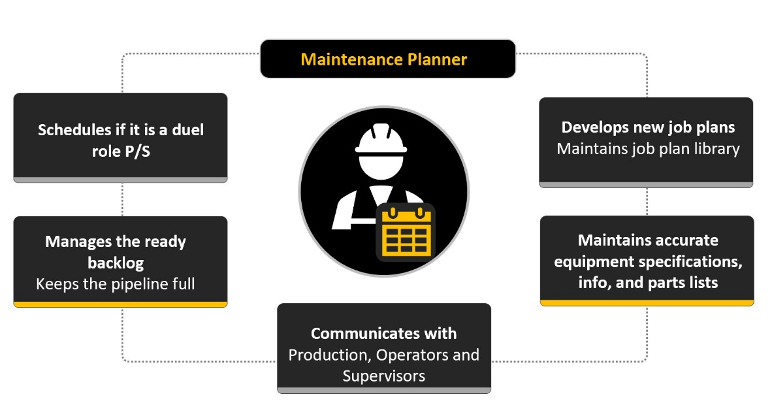

Core maintenance planner responsibilities

In Isenhour’s view, if planners aren’t prioritizing the tasks in Figure 1 (above), then they’re not planners; they’re schedulers. A true maintenance planner writes job plans and then thinks through the work before scheduling it. The role is broader than distributing PMs. Effective planners also arrange for the corrective maintenance work that comes out of PM inspections.

While scrutinizing what your planner IS doing, also pay attention to what they should NOT be doing. Here are the top eight things that planners shouldn’t be doing, in Isenhour’s view:

- Planning emergency work

- Expediting parts

- Acting as a relief supervisor

- Maintaining the storeroom

- Acting as a clerk

- Performing the buyer function

- Picking up tools and filling in

- Engineer/design jobs

Because it is easy and common for planners to get pulled into these other roles, Isenhour recommends printing out these eight factors to have as a visual reference.

How to implement effective maintenance planning

To course-correct, if necessary, and adopt more effective maintenance planning practices at your plant, Isenhour recommends these 10 areas of improvement:

- Work execution business processes

- RASCI (Responsible, Accountable, Supporting, Consulted, Informed) or RACI

- Step text (workflow and process documentation)

- Planner and scheduler job descriptions built from the RASCI or RACI

- CMMS or EAM usage expectations for all affected

- Job plan library expectations

- Job plan expectations with precision maintenance standards

- Scheduling template

- Bill of Materials expectations

- Kitting expectations

“Good processes drive good planning,” Isenhour said.

Start your evaluation, he said, by looking at the “mega” processes, with a specific eye to whether larger plan systems support the planner doing his or her appropriate job. Then, approach from the other direction and examine (or create) RACI level job descriptions, so that everyone is clear what they are directly responsible for (versus just supporting).

You may find yourself having to update job descriptions beyond just those for maintenance planners. “Job plans are a disaster for a lot of folks,” Isenhour said. They are old and focused on who to hire, not how to do the job.

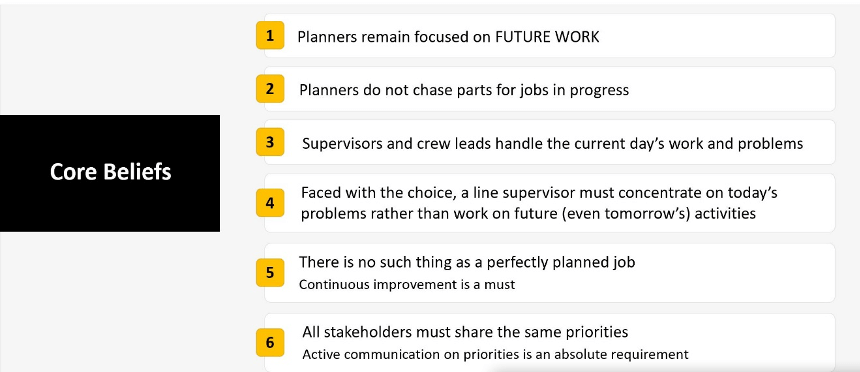

Isenhour’s webinar presentation includes examples of all 10 improvement areas, including templates and strategies to follow. His talk also continually comes back to the sacred truths of maintenance planning, as listed in Figure 2.

Other recommendations include utilizing your CMMS to document and drive correct business processes and maintaining a job plan library to avoid redoing job plans each time they’re needed. Your goal should be to get job plans to where they can provide correct time estimates for work needed and labor hours required.

For more details about each of the processes Isenhour recommends, listen to the complete webinar on Accelix.com.