Manufacturing’s transformative path to the IIoT

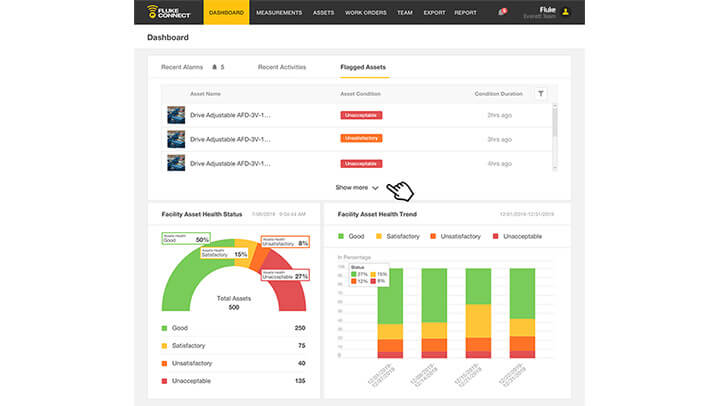

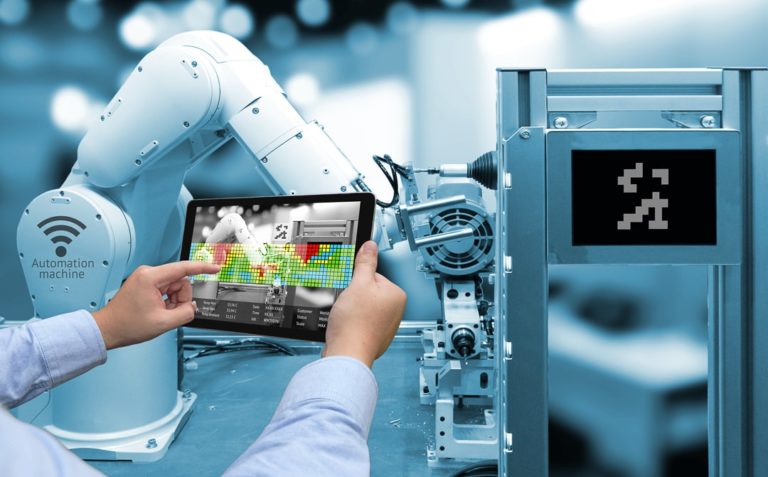

Download the white paper Examining key drivers to help us forecast what’s ahead Manufacturing operations are predicted to be one of the biggest winners of the Industrial Internet of Things (IIoT) transformation. Using condition monitoring sensors and software, innovators have an opportunity to wirelessly leapfrog over brownfield infrastructure, automate asset-health data collection, and feed it…