Simplify Your Maintenance Strategy—Connected Reliability in Action

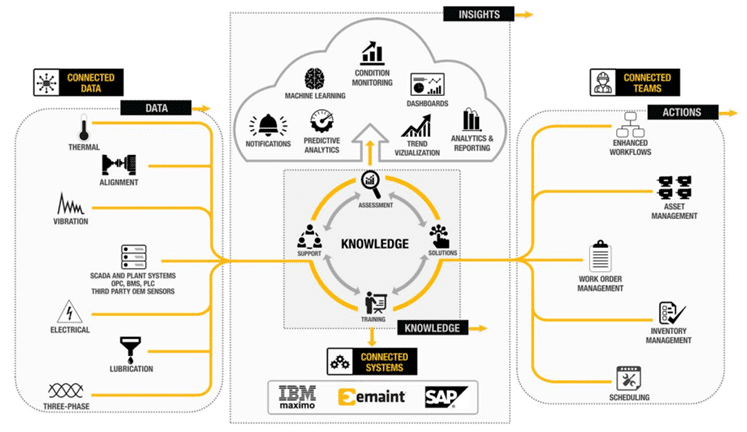

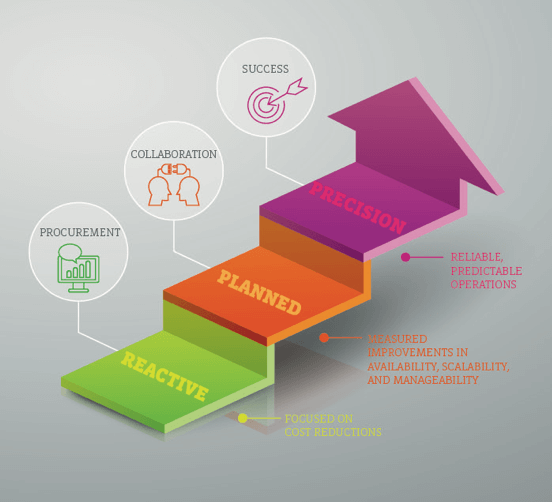

This webinar will explore the theory and principles of maintenance strategy, highlighting how predictive and prescriptive techniques—when supported by the right technologies—can transform reliability outcomes. Building on this foundation, the session will feature a practical case study demonstrating the application of Fluke Azima’s connected reliability technology to drive measurable improvements, offering a real-world perspective on…