The Hive: The machine whisperer

Condition monitoring and predictive maintenance are a safer way to “listen” to your assets.

Condition monitoring and predictive maintenance are a safer way to “listen” to your assets.

A good ear should be your maintenance team’s first line of defense.

Connected reliability is more than just a hashtag; it’s a means to achieve optimal predictive maintenance.

Remember to sign up for Wednesday’s live event.

Proactive maintenance makes it possible to perform maintenance only when necessary.

When older workers retire and there’s a lack of qualified candidates to replace them, what do you do?

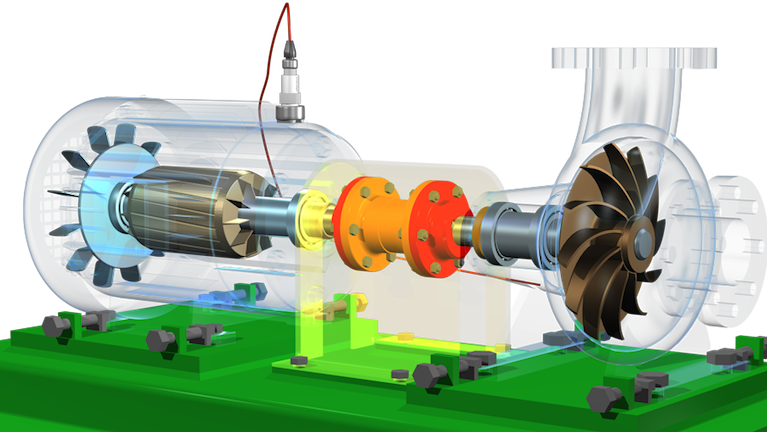

The Internet of Things (IoT) and the Industrial Internet of Things (IIoT) are increasingly becoming more commonplace terms in the world of maintenance, reliability and asset management. This technology interconnects billions of devices and equipment, allowing for greater system collaboration. IIoT has the opportunity to reduce the need for intrusive maintenance and provide insights to the actual condition…

Infrared sensors can seamlessly integrate with a software platform that gathers data from many other sensor types.

Join us at the 22nd annual Maintenance and Reliability Conference! MARCON 2018, which will be held March 12-15, 2018, at the Knoxville Convention Center in Knoxville, Tennessee. Our subject matter experts will be at Booth 9 in Ballroom A showcasing Fluke’s prestigious line of maintenance and reliability software tools and sensors. Make sure to stop by to learn…

For any facility or plant, profitability is dependent on continuous cost reductions at the physical asset level using a data-driven strategy. That’s where Computerized Maintenance Management System software (CMMS) helps answer the call. A CMMS is an essential tool to help manage asset lifecycles. It also helps carry out asset management plans, manage risk, measure…