Maintaining Reliable Assets, a Resource Constraint Economy

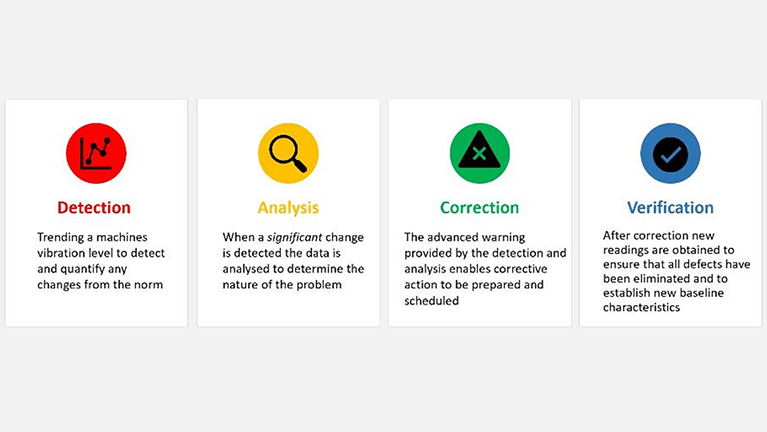

This webinar discusses the labor constraints and experience constraints companies are facing when it comes to maintaining the health of their assets. Discover strategies to optimize asset management despite workforce shortages and how companies leverage technology and expertise to overcome experience-related hurdles. Speaker:Michael DeMaria, Product Manager for Azima DLI, a Fluke Reliability Company Michael is the Product…