Articles

How power monitoring software can save your budget and business

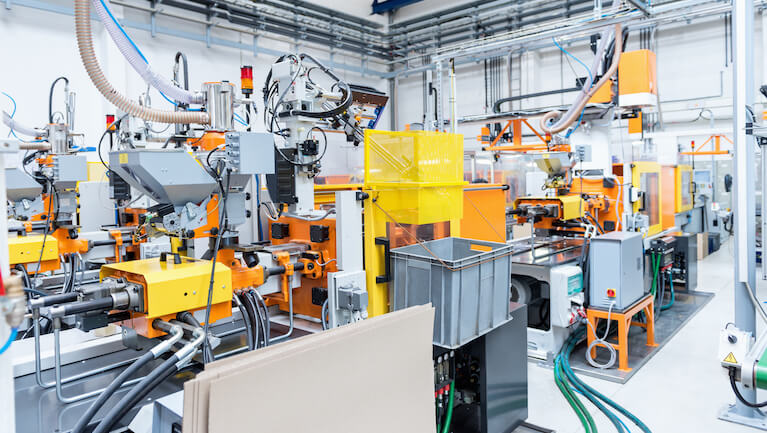

Optimize performance and prevent downtime Imagine a machine that stamps plastic parts. It has three different phases coming into the asset, and occasionally, one of those phases becomes unbalanced. An unbalanced phase affects the proper functioning of the asset because the motor or pump increases its power consumption and does not work as designed. This…

Plant Services-Fluke predictive maintenance webinar now on-demand

Plant Services and Fluke hosted a webinar on July 24 discussing predictive maintenance (PdM) and its impact on budgets, productivity, and efficiency. Fluke experts, John Bernet CMRP and Frederic Baudart CMRP, dove into the effects, implementation, and challenges of deploying a predictive maintenance program. “You can have 25-30% cost reduction by having a good maintenance…

Go paperless with CMMS software

Searching for and recreating lost paper documents costs organizations mightily. Those with 1,000 employees spend approximately $2.5 million to $3.5 million per year on such tasks, according to the research firm International Data Corp. Computerized maintenance management system (CMMS) software not only helps you standardize and automate maintenance activities but also provides you with a…

How to Make Data-driven Decisions with Connected Reliability

The push to transition to more sophisticated digital tools, such as computerized maintenance management systems (CMMS) software and condition monitoring sensors, is inescapable. By integrating condition monitoring data with CMMS software, maintenance and reliability (M&R) professionals receive an overall view of asset health and maintenance activities in real-time—all in one place. Gather the data Most…

Pairing the P-F Curve with Condition Monitoring

The P-F Curve is a concept illustrating an asset’s progression toward failure. The X-axis of the chart represents the time to failure, beginning with an asset’s design and installation, and the Y-axis represents an asset’s resistance to failure. Potential failure, or PF, is a detectable state of failure, or the point when degradation begins. Functional failure, or FF, is when the asset has reached a…

Potential-Failure (P-F) Curve FAQ

The Potential Failure (P-F) Curve is a visual tool for communicating the condition of a component and its decline toward failure. With an optimized maintenance program, you can prolong the time until failure takes place and schedule needed maintenance actions for the most convenient times. What is the purpose of the P-F Curve? The P-F…

How to Detect and Prevent Roller Bearing Failure

Lubricated roller bearings are like a well-hydrated person. More likely to be reliable when it matters. Learn more here!

4 Keys to Condition-based Maintenance

The IIoT offers opportunities to increase asset reliability using condition-based maintenance (CBM). Apply these four steps to ease adoption!

Engineering safer environments with remote sensors

Governments have passed laws holding businesses responsible for providing employees with a safe working environment. Workplace conditions that pose a risk to personnel should be avoided or training completed to minimize hazards. Thankfully, advances in technology are making it easier for facilities to improve worker safety by decreasing contact personnel have with running machinery or…