The Connected Reliability Starter Kit – Taking Asset Management to the Next Level

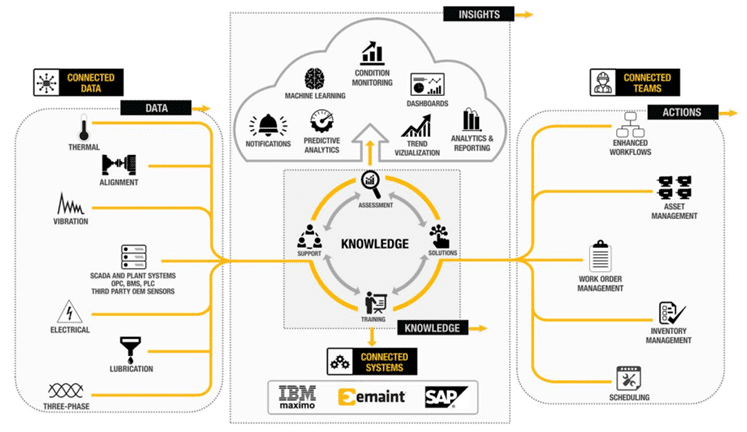

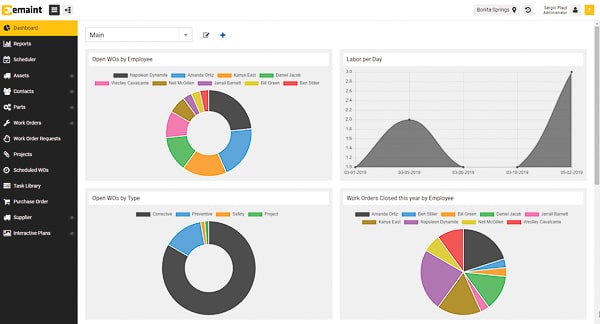

This webinar will explore best practices in enterprise-wide visualization and multi-experience engineering, with a focus on optimizing asset performance strategies. Attendees will learn how to apply tools such as Reliability Centered Maintenance (RCM), asset strategy simulation, and Failure Mode and Effect Analysis (FMEA) to define, measure, and continually improve their asset strategies. The session will…