How to Apply Ultrasound Technology to Extend Bearing Life

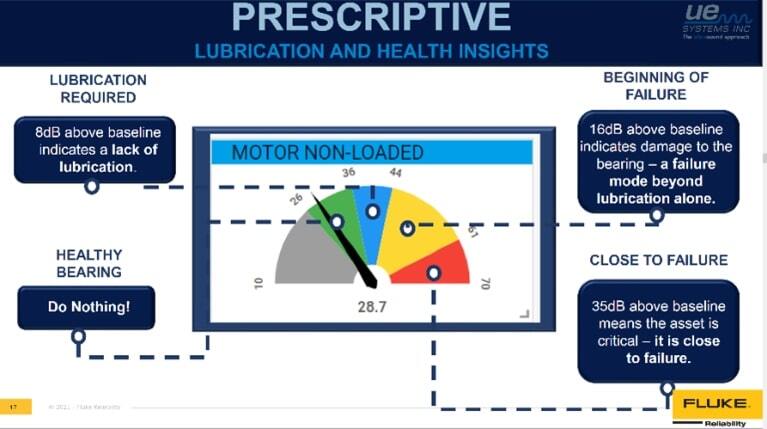

Under lubricating or overlubricating a bearing can destroy it and bring production to a halt. Although there’s always going to be a certain amount of friction, maintaining just the right quantity of lubrication will keep it at an acceptable level. In his July 2021 Accelix best practices webinar, Blair Fraser, global director of IIoT Solutions…