8 Reliability and Maintenance Trends to Watch

It shapes up to be an interesting decade, with massive changes expected to unfold in how maintenance and reliability professionals.

It shapes up to be an interesting decade, with massive changes expected to unfold in how maintenance and reliability professionals.

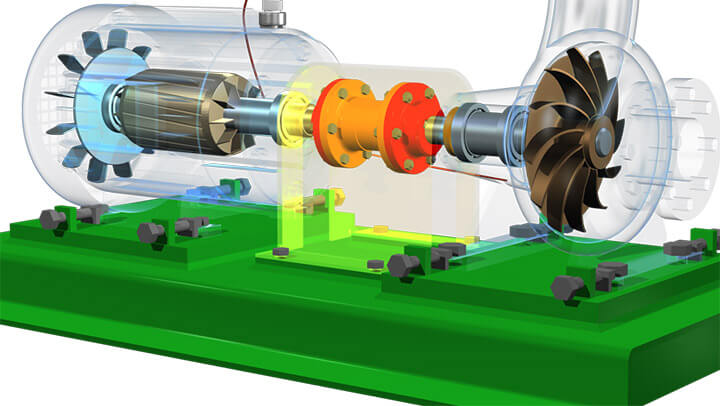

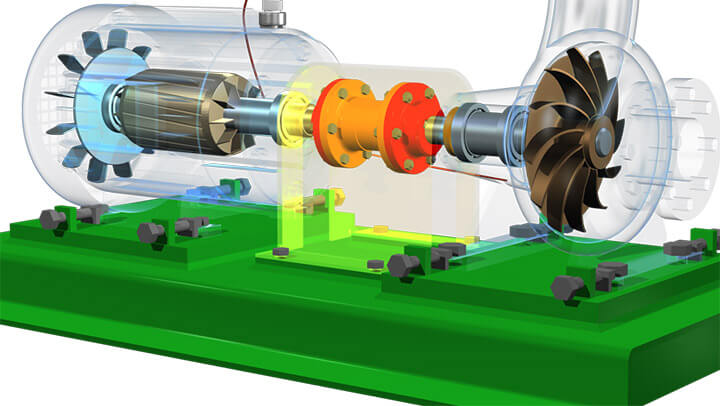

Roughly two-thirds of all rotating machinery experience a condition called “soft foot”. Learn how to recognize and avoid this common issue.

In presenting on leadership strategies to improve culture and performance among maintenance and reliability teams, leadership expert and consultant Tom Moriarty uses neuroscience to explain that successfully enacting change is often harder than people expect it to be. Moriarty titled his Accelix Best Practice Webinar, “Productive leadership: How to create the culture and performance you…

Planning for Industry 4.0? To achieve higher reliability and related goals—such as a better environmental footprint, lower energy costs, sustained or improved product quality, and so on—you need to prepare your people for a smooth and successful transition. In this one-hour webinar, reliability expert Jack Nicholas discusses how to plan for managing assets and people…

By Pamela Curry, Inframark Special Projects Manager Reprinted with permission from the Inframark newsletter, The Source, October 2019 Inframark’s first eMaint system went live in mid-2018, kicking off an effort to put in place a common computerized maintenance management system (CMMS) platform at all Inframark ConOps projects. When we started, projects were using a variety…

A key benefit of eMaint Computerized Maintenance Management System software is how it organizes assets by building, campus, and global locations. Cross-location asset management refers to assets set up in multiple places—near or far. One of the benefits of using eMaint computerized maintenance management system (CMMS) software is cross-location asset management. Within eMaint, users can…

Hackers continue to inflict more and more damage on enterprise companies’ networks, and manufacturing is seen as one of the world’s most exploitable industries. According to a 2019 IBM X-Force report, manufacturing ranked fifth among the top 10 most frequently targeted industry sectors. Today’s condition monitoring sensors and other Wi-Fi-enabled devices possess connecting capabilities and…

What will 2020 bring in terms of automation, AI, machine learning, and Industry 4.0? What takeaways do we have from 2019? What new could happen that we don’t know about? Oliver Sturrock, Chief Technology Officer for Fluke Reliability Solutions, takes a look at the trends driving change in our industrial world. Oliver Sturrock, CTO,…

Soft foot is a common problem that affects rotating machinery and can result in a range of mechanical and quality problems. Think of it as a chair with one leg shorter than the other three. Soft foot is frequently overlooked but the consequences of ignoring its symptoms can be serious and expensive. In this…

Key takeaways from October 2019 webinar by Dr. Klaus Blache As reliability professionals, we’re predisposed to prioritize the most critical assets. But what if someone told you that asset prioritization wasn’t the key to improving reliability maintenance? Dr. Klaus Blache, director of the Reliability and Maintainability Center (RMC) at the University of Tennessee (Knoxville), has…