What are World-Class Maintenance Performance Metrics?

In this Best Practices Webinar, we discuss how to achieve the best performance metrics results.

In this Best Practices Webinar, we discuss how to achieve the best performance metrics results.

What do you do first when implementing a new CMMS? Here’s our top tips for how to prepare your operations for a CMMS system.

A computerized maintenance management system (CMMS) provides more than a place to maintain and manage assets and workflows. It’s also a place packed with usable data that, when analyzed in detail, enable deeper opportunities for directing and improving maintenance repair and operations (MRO) decisions. In an Accelix best practices webinar (BPW), Nicole Rochelle, business intelligence…

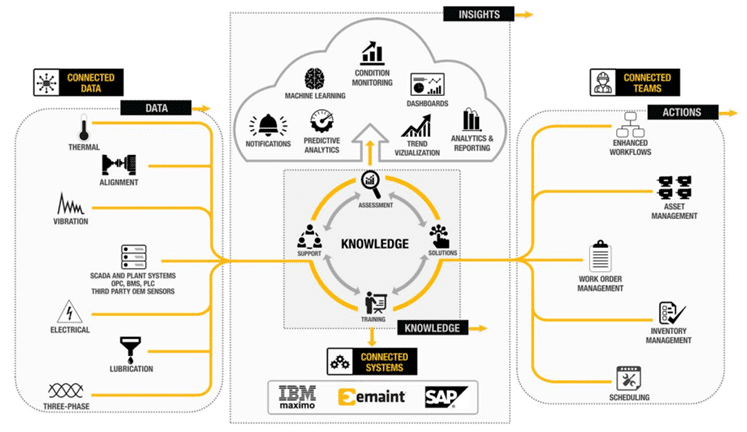

You may be surprised by how supercharged your CMMS can be when connected to more powerful sensors, software, and other compatible systems. Your CMMS is designed to support maintenance and reliability, and the outcomes only get better with systems that interoperate. Integrations can be painless and can set your company up for years to come….

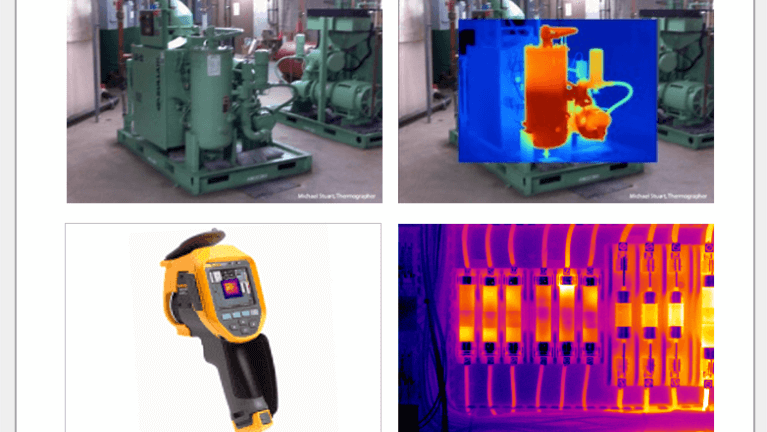

Here’s a common scenario: Your maintenance team already uses thermography to inspect critical assets, either via an in-house person trained to use an infrared camera or via a service. Inspections are performed on a regular basis and when a change in asset operating temperature is detected compared to the previous inspection, a flag goes up…

It can be challenging to keep a university housing system working properly with effective work order management and forecasting abilities of future maintenance requirements. One university housing office began searching for an efficient way to automate work order and asset management with a computerized maintenance management software (CMMS) system. The univeristy’s housing assets include five…

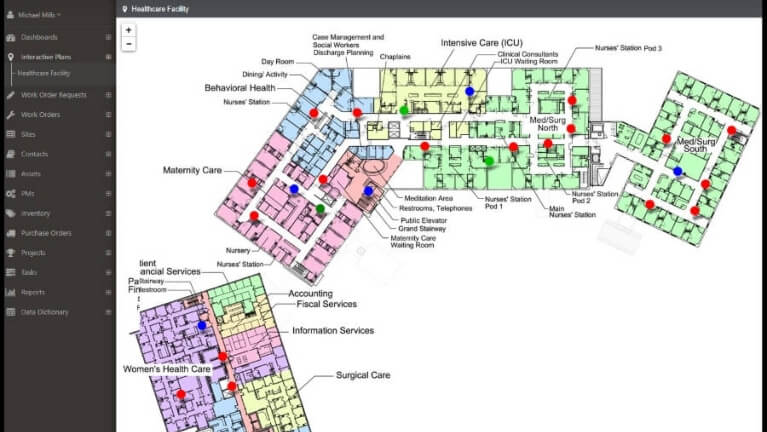

Spatial Intelligence is the human ability to visualize with the mind’s eye. Reality capture technology allows us to add a digital version of the mind’s eye to our maintenance process and asset management tools. Imagine a world where you can find each asset at your fingertips, ensuring all your decisions, as well as your system…

Condition monitoring and vibration analysis are separate processes, but both are vital indicators of machine health and require the collection of accurate data to analyze issues and trends. Colin Pickett is a consultant and former Prüftechnik engineer with 35 years of reliability and vibration analysis experience. He takes us through these processes, describes what to…

Asset health management programs fail more often than they succeed. In this webinar, we share the top five reasons such programs fail and how a cloud-based, connected thermography program can help overcome these challenges. Michael A. Watson, Product Application Specialist with Fluke Reliability, outlines the people, processes, and technology to build a sustainable program. A…

This presentation by CMMS deployment expert Scott Rojas of Fluke Reliability outlines the pre-implementation process we call the AIM. The AIM provides a detailed look at a company’s alignment on its business strategy and capabilities; project engineering, compliance, scoping, and other CMMS requirements; plus goals, objectives, and expected ROI. AIM seeks to reduce pitfalls that…