CMMS – 10 Key Steps Methodology

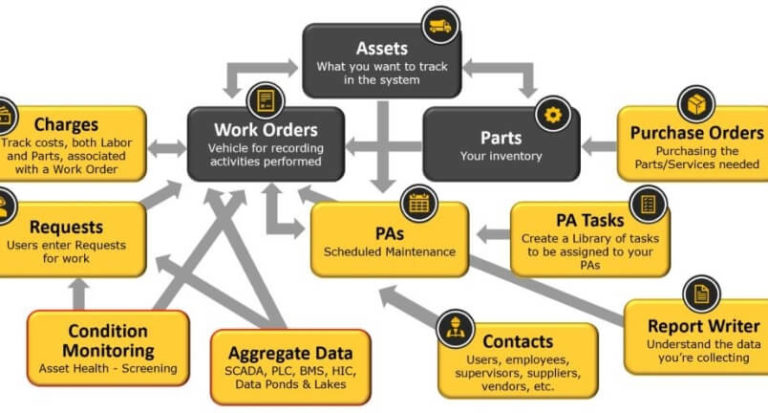

Most CMMS systems by nature are neither intuitive nor simple to understand. Here is where the adoption of a “best practice” CMMS Implementation methodology can be worth its weight in gold by ensuring the fundamental 3 C’s (consensus with clarity and certainty) are instrumental in the decisions you are making. This is definitely a great…