Slow-speed and Early Fault Detection, How to Solve

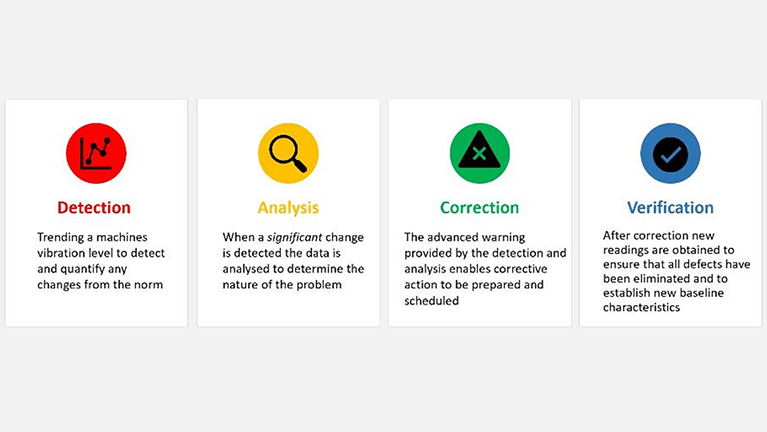

This webinar will introduce you to Azima DLI’s proprietary diagnostic technique, Impact Demod. This powerful tool allows analyst to get deeper insights into the vibration data for rotating assets, providing improved visibility to the source of vibration, extending the application of vibration analysis to slower speed assets, and finding early bearing faults to properly plan for…