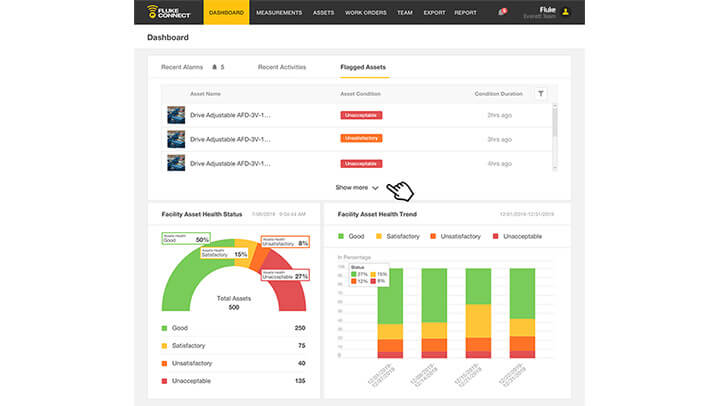

Increase condition monitoring success by utilizing process parameters

Deploying a condition monitoring program to better track asset health and performance can have the effect of narrowly focusing the team on one or a few types of data. Typically, maintenance and reliability professionals install a sensor such as an accelerometer on machines to measure vibration and relay that data to a vibration analyst to…