Transforming Maintenance Teams for the Future

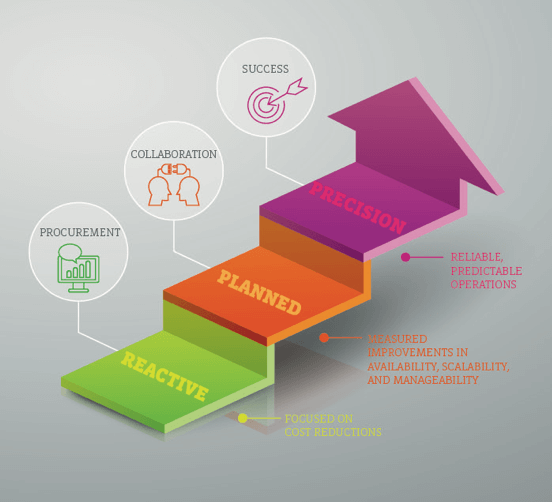

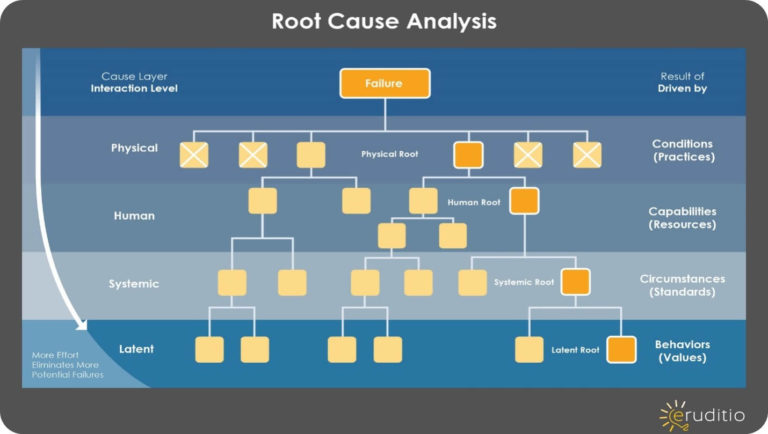

Since the late 90s, maintenance team leaders have struggled to make their teams more efficient and “World Class.” Root Cause Analysis is essential to understand when and why these inefficiencies began. Leaders need to change their mindset about where to find future maintenance associates, focusing on the MT (Maintenance Team) Factors: MT Factor #1: The…