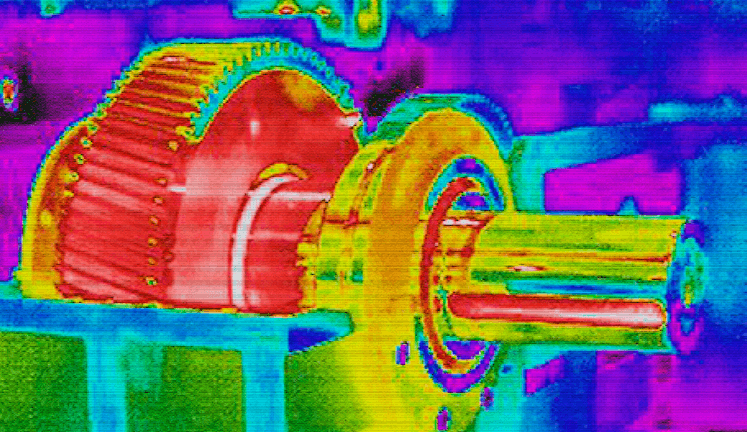

Thermography as a condition detective: The secret sauce to uptime

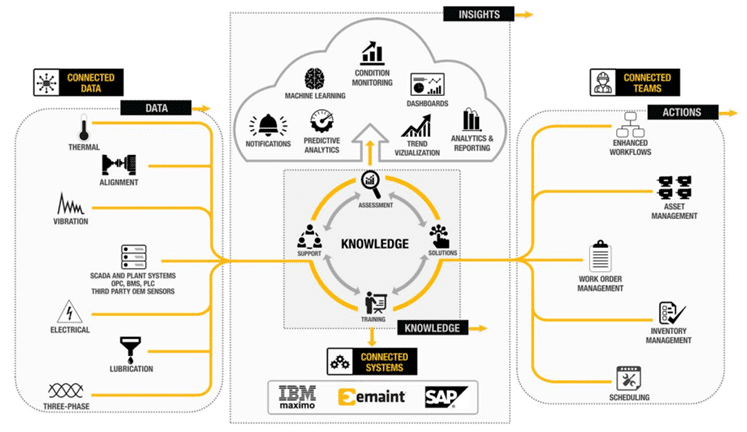

Subject-matter expert Craig Haase provides a primer on thermography in maintenance and reliability and how it can powerfully unearth details surrounding your machines’ condition and health. Haase will detail customer scenarios and use cases, highlighting how thermal imaging solutions can record, provide alarm notifications, and monitor assets 24/7 regardless of location. He will also discuss…