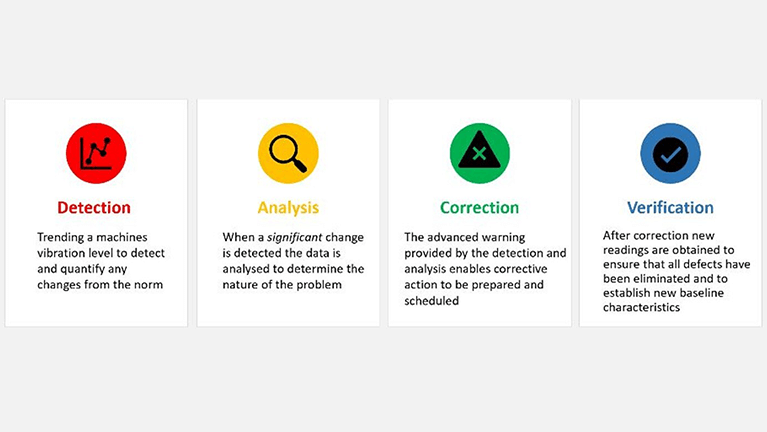

Industry expert Colin Pickett offers best practices for condition monitoring and vibration analysis

With more than 35 years of experience helping educate customers on the finer points of asset condition monitoring and vibration analysis, including 15 years as a Prüftechnik engineer, Colin Pickett has developed an authoritative list of best practices. Now a full-time consultant and trainer, Pickett shared his depth of knowledge at a November 2020 Fluke…