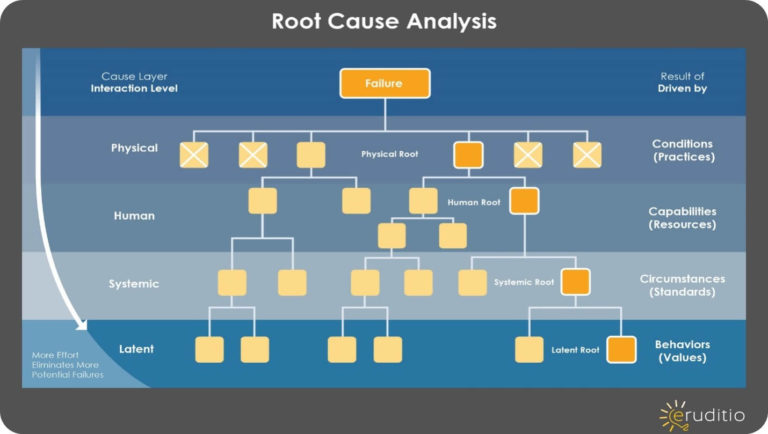

Root Cause Analysis

What is the most effective method? Does your company perform Root Cause Analysis (RCA) or just failure analysis? What distinguishes these tools and when are they appropriate? Does your company have a written policy or procedure? Are these performed routinely after an incident or notable failure? Listen to one company’s process, challenges and successes in…