10 steps to getting your CMMS implementation right (the first time)

The stakes are high for companies planning or implementing CMMS systems at this time.

With all the changes to standard work procedures created by the pandemic, computerized maintenance management system (CMMS) software has emerged as a tool of choice for integrating teams, digitalizing workflows, and implementing revised procedures for increased employee safety. More eyes on CMMS success can mean more managerial support, budget, and team buy-in. But it also raises the importance of finding the right system and getting it implemented successfully.

Gregory Perry, a Senior Capacity Assurance Consultant with Fluke Reliability, has nearly two decades of experience in maintenance and operational best practices, with a particular focus on CMMS implementations.

Perry coaches facility managers on “10 keys to CMMS implementation success,” the title of a June 2020 webinar he presented for Fluke Reliability. You can watch the full replay of this webinar at Accelix.com.

“The CMMS is really a tool that you use in the course of your day to day maintenance operations,” he says, adding, “But, it is NOT a magic wand. You will never software yourself to reliability.”

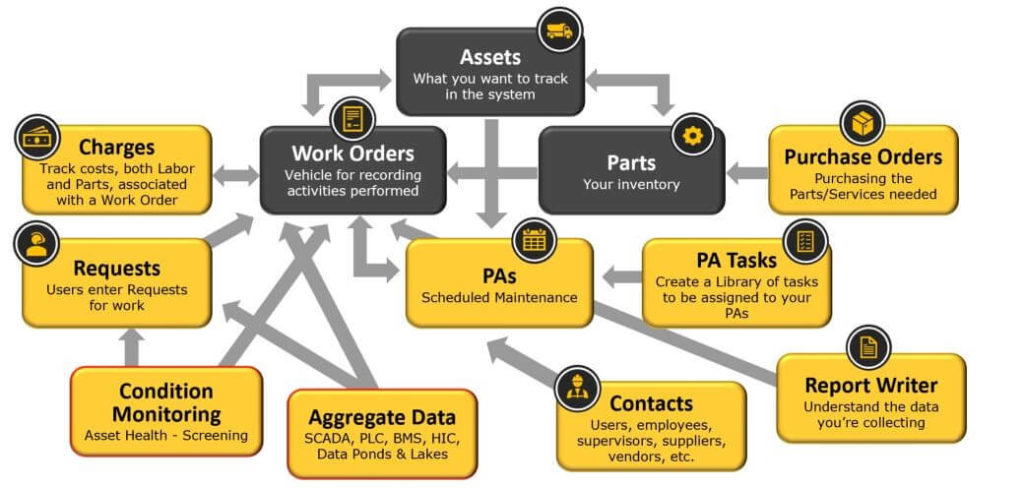

A CMMS has three high-level purposes (in no particular order):

- Historian of empirical and physical data storage

- Manage and control work management/parts usage processes

- Track maintenance activity over the lifecycle of an asset

Implemented correctly and optimized for use, a CMMS can tell the full story of asset health and asset management. It can also reduce operational costs and manual processes, increase customer satisfaction, visibility and productivity, meet regulations, and become a cornerstone of work execution management.

Planned implementations are the most successful. Perry’s 10 elements are most effective when followed in sequential order. What follows here is a brief synopsis; to receive the full benefit of Perry’s coaching, watch the webinar replay online.

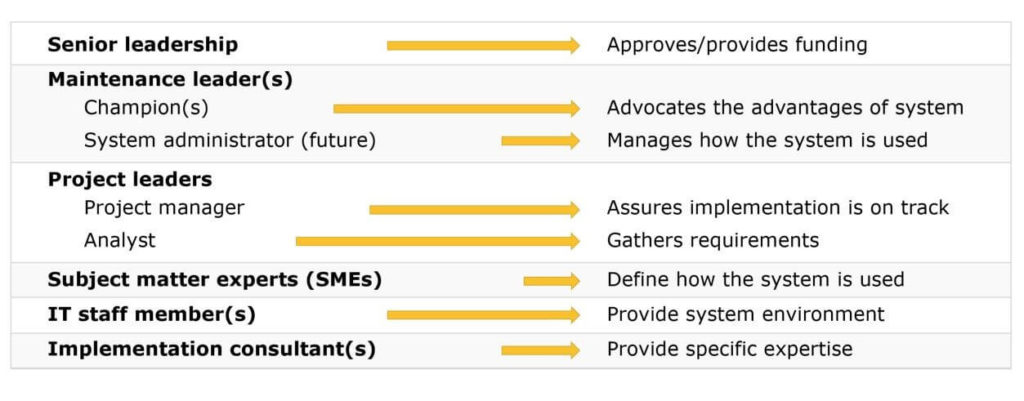

1. Implementation team

The CMMS needs to be a shared vision across senior leadership, maintenance leaders, project leaders, subject-matter experts, and IT staff. Your first step should be to create a cross-functional implementation team. Identify your champions and enlist the support of an implementation consultant.

2. Core team familiarization

Encourage everyone on the team to spend their time on due diligence. While it’s OK for people to focus on their core implementation areas (inventory vs. work orders, for example), everyone needs to have a solid understanding of the overall system. Perry advises that the core team complete training before moving forward to avoid making incorrect assumptions about what the system does or does not do.

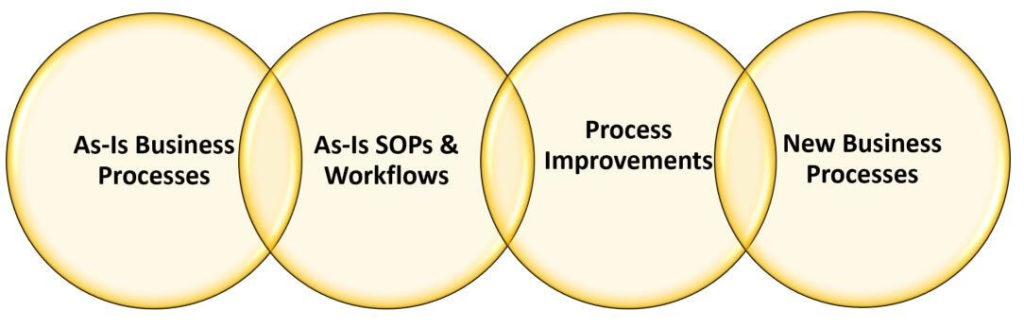

3. Workflow and SOPs (standard operating procedures) to PCDs (process control documents)

Document your existing workflows, job descriptions, roles and responsibilities, metrics, and processes before implementing the CMMS. As Perry says, “It’s OK to document what may be a broken process – at least it is a process to document. Later on in the implementation process is NOT the time to figure it all out.”

Once you have your baseline mapped, then you can start adapting workflows to the CMMS. “It’s inevitable that you will either need to adopt new business processes to adapt to your new CMMS OR that your new adopted CMMS platform will have to adapt to your processes.” Be aware, he advises, that software can be hard to change.

4. Data standardization

What is your data going to look like? Is it standardized? Everything from the vocabulary – what you consistently call things – to maintenance codes, job status, and intervals needs to be defined and standardized. Consistent data formats can be tracked, trended, and shared; it’s more trustworthy, and trust engenders system usage.

5. Implementation plan

What does the team need the system to do? Make this a cross-functional exercise. Utilize your training from Step 2 and your process documentation from Step 3 to start building the plan. Perry cautions against biting off too much. “Done is better than perfect,” he says.

6. Data assimilation and validation

Asset data is critical for the success of your CMMS implementation, Perry says, but only if you have the right amount of quality data. You may need to collect additional data to reach a workable state. You may also need to assimilate data across different systems; lean on your implementation consultant for help and adhere to the standardization established in Step 4.

7. System configuration/acceptance testing

Setting up your system to receive data involves creating and configuring forms, fields, dropdowns, and workflows. Refine the process flows and then run acceptance testing — pick an asset and follow it through the system.

Perry recommends making sure that all users have what they need at this stage. He also cautions going too heavy on data requirements, or your new system may overly tax the users and damage buy-in.

8. Training main users

Now comes training – for all users of the system implemented at your facility. “You need their adoption to make this succeed,” Perry says. Feel free to adjust the training content by role, as most people won’t need to know every aspect of the tool.

9. Go-live strategy

Consider rolling out one section of the new CMMS at a time, soft-launch style.

“Get your ducks in a row.” Set milestones and consider the process continuous and ongoing.

10. Process auditing

Revisit your key metrics. Are you collecting the right data, and are the metrics informing your processes? Adopt a continuous improvement approach. Form a review team at go-live and be on alert for bad habits.

Apply these 10 steps to success over and over for each milestone on your CMMS journey. Continue to map your business processes and incorporate feedback from the team. For more coaching from Greg Perry, watch the full webinar online.

10 keys to CMMS implementation success

- Implementation team

- Core team familiarization

- Workflow and SOPs to PCDs

- Data standardization

- Implementation plan

- Data assimilation and validation

- System configuration/acceptance testing

- Training main users

- Go-live strategy

- Process auditing