What are World-Class Maintenance Performance Metrics?

In this Best Practices Webinar, we discuss how to achieve the best performance metrics results.

In this Best Practices Webinar, we discuss how to achieve the best performance metrics results.

A computerized maintenance management system (CMMS) provides more than a place to maintain and manage assets and workflows. It’s also a place packed with usable data that, when analyzed in detail, enable deeper opportunities for directing and improving maintenance repair and operations (MRO) decisions. In an Accelix best practices webinar (BPW), Nicole Rochelle, business intelligence…

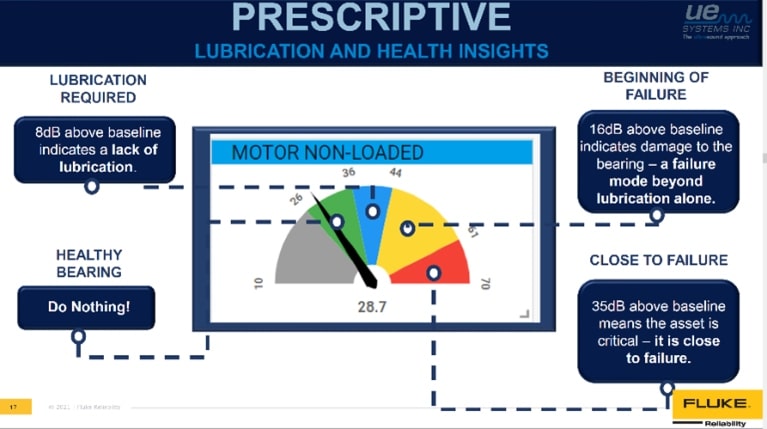

Under lubricating or overlubricating a bearing can destroy it and bring production to a halt. Although there’s always going to be a certain amount of friction, maintaining just the right quantity of lubrication will keep it at an acceptable level. In his July 2021 Accelix best practices webinar, Blair Fraser, global director of IIoT Solutions…

If you’ve been waiting until the time is right to begin focusing on your Industrial Internet of Things (IIoT) initiatives, you just might be waiting too long. The fact is that the concept of interconnected applications, equipment, and technology is more than just an abstraction. The IIoT market is forecast to grow to $110.6 billion…

It can be challenging to keep a university housing system working properly with effective work order management and forecasting abilities of future maintenance requirements. One university housing office began searching for an efficient way to automate work order and asset management with a computerized maintenance management software (CMMS) system. The univeristy’s housing assets include five…

Get ready to explore a wide range of cutting-edge topics to improve your reliability at the Xcelerate20 virtual conference November 17-19, 2020. This three-day event provides numerous opportunities to see firsthand (from your phone or computer) how the latest software, tools, and processes can help you fine-tune your 2021 maintenance plan. Get inspired by our…

Like a successful reliability program, an effective workplace safety initiative requires getting the entire team on board. Workplace safety issues only abate when everyone understands and actively supports a zero-incidents goal. The difference between improving safety (or reliability) or continuing to experience problems comes down to culture. Safety expert Chuck Pettinger of Fortive-owned Predictive Solutions…

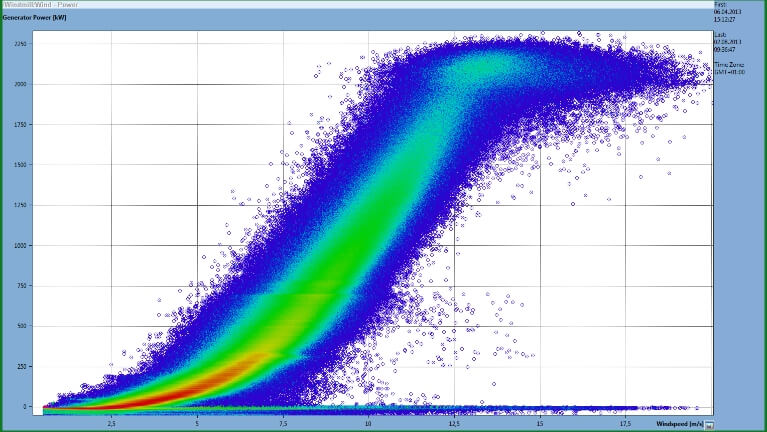

Deploying a condition monitoring program to better track asset health and performance can have the effect of narrowly focusing the team on one or a few types of data. Typically, maintenance and reliability professionals install a sensor such as an accelerometer on machines to measure vibration and relay that data to a vibration analyst to…

By Brian Harrison According to a Fluke survey done in late 2019, some 50% of maintenance and reliability teams were actively planning Industrial Internet of Things (IIoT) initiatives. This, of course, was before the massive change brought upon us all by the spread of the coronavirus. Still, at the time, more than half of those…

At a time like this, when normal is abnormal and abnormal has become business as usual, it can be useful to find out how your peers are approaching their maintenance strategies. That’s why we at Fluke worked with Plant Services this spring to survey more than 200 maintenance and reliability professionals to assess how the…