Preventive Maintenance Articles

Gain deep insights into bearing health with ultrasonic analysis

Friction is inherent in all machine bearings. When this friction starts to change, ultrasonic analysis can tell us a lot about what is happening in that bearing. When both friction and impact monitoring…

Defect elimination programs change the culture by solving lots of little problems first

A defect elimination program targets the smallest, most irritating problems in a plant. It does so by giving everyone a stake in improving daily work life by eliminating errors and faults. In the…

The exponential power of daily improvement

Calvin Williams has helped numerous companies build continuous improvement programs. In this webinar, he discusses the science behind daily improvement and how to use it to create a sustainable culture of continuous improvement….

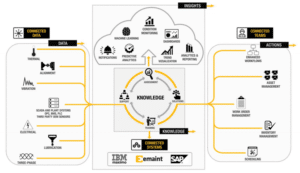

Get more value from your CMMS (Part II): Integrations for improving machine health

You may be surprised by how supercharged your CMMS can be when connected to more powerful sensors, software, and other compatible systems. Your CMMS is designed to support maintenance and reliability, and the…

Get more value from your CMMS (Part I): Best usage models for business impact and user adoption

Some of the most game-changing features and usages of a computerized maintenance management system (CMMS) often get overlooked. That’s a drag on your ROI and can be rectified by simple instruction and training….

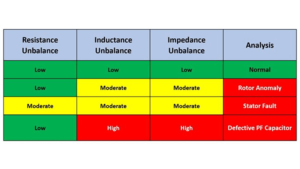

A look at the two principal motor testing methods: de-energized and energized

Every industrial facility has motors. They may range in horsepower, age, OEM, and criticality, but they’re still the most common asset facing maintenance and reliability (M&R) teams. According to the Electric Power Research…

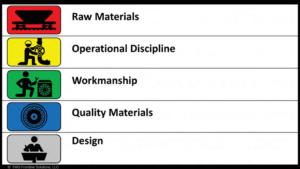

How a defect elimination program works and why it could work for you

“Defect elimination” has become a hot topic in the reliability world. But what exactly does it mean? Defect elimination is a bottom-up approach that uses small teams tackling small projects with broad participation….

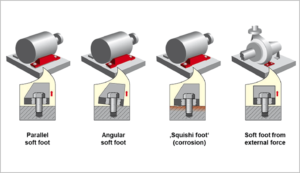

Industrial machine alignment: Tips for getting precise measurements in demanding conditions

Mines, sawmills, and pulp and paper plants represent some of the toughest environments to maintain machine alignment. Matt Joinson, the owner and operator of Jaffray Millwright and Welding, located in Jaffray, British Columbia,…

Breaking down lubricant degradation by failure mode for reliable oil analysis

To successfully integrate oil analysis into your machine reliability practices, you must first understand how lubricants degrade. That point was made exceedingly clear by lubricant expert Sanya Mathura in a January 2021 webinar…