Preventive Maintenance Articles

Why we can’t proceduralize everything

Unwanted errors & surprises are serious threats to reliability in any high-hazard industry. To address them, many leaders apply a mechanistic approach. They install controls, write procedures, and enforce compliance. But these mechanistic…

What happens after the alignment?

Don’t be left in the dark. Alignment processes should include post monitoring to protect the asset and confirm a proper alignment. Elongate the life of your machines with these tips, tricks and technologies…

The Daily Benefits of a Continuous Improvement Plan

It’s one thing to say you’re going to do something to improve continuously every day, like exercising, is one thing. Following through is another. It takes discipline. In an Accelix best practices webinar…

How to Apply Ultrasound Technology to Extend Bearing Life

Under lubricating or overlubricating a bearing can destroy it and bring production to a halt. Although there’s always going to be a certain amount of friction, maintaining just the right quantity of lubrication…

What cybersecurity risks do maintenance and reliability teams face—and what can they do about it?

Know thy enemy. This has never been truer than in the field of cybersecurity, right now. With ransomware attacks escalating by the day, maintenance and reliability teams at critical facilities, government organizations, and…

Future-proofing asset dependent firms against talent flight

Talent risks now represent a significant threat to asset dependent firms. In addition to the sheer unavailability of talent, there is the increasingly competitive environment to attract talent. The stark reality is that…

Managing cybersecurity risk in maintenance and reliability

Maintenance and reliability teams increasingly utilize a range of technologies, systems and devices—all of which can present cybersecurity risks. For this presentation, cyber expert Matthew Hudon and CMRP Frederic Baudart are joining…

Vibration monitoring for peak asset performance

Vibration monitoring alerts teams to changes in machine condition before the situation degrades enough to cause harm. With a solid mix of monitoring and in-person evaluation, maintenance teams can move closer to condition-based-maintenance,…

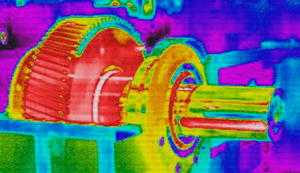

Thermography as a condition detective: The secret sauce to uptime

Subject-matter expert Craig Haase provides a primer on thermography in maintenance and reliability and how it can powerfully unearth details surrounding your machines’ condition and health. Haase will detail customer scenarios and use…