Reliability Articles

The Hive: Vibration monitoring saves time

In this edition of The Hive, our bees are working hard… or hardly working. By harnessing the power of predictive maintenance and condition monitoring, they’re working smarter and playing harder than ever before.

Potential-Failure (P-F) Curve FAQ

The Potential Failure (P-F) Curve is a visual tool for communicating the condition of a component and its decline toward failure. With an optimized maintenance program, you can prolong the time until failure…

How to Detect and Prevent Roller Bearing Failure

Lubricated roller bearings are like a well-hydrated person. More likely to be reliable when it matters. Learn more here!

4 Keys to Condition-based Maintenance

The IIoT offers opportunities to increase asset reliability using condition-based maintenance (CBM). Apply these four steps to ease adoption!

Engineering safer environments with remote sensors

Governments have passed laws holding businesses responsible for providing employees with a safe working environment. Workplace conditions that pose a risk to personnel should be avoided or training completed to minimize hazards. Thankfully,…

Closing the Operations-Maintenance Gap

Over the last 20 years, there have been major advancements in maintenance technology. Evolutions—whether in Computerized Maintenance Management System (CMMS) software or Enterprise Asset Management (EAM) systems, such as Maximo—have focused almost exclusively…

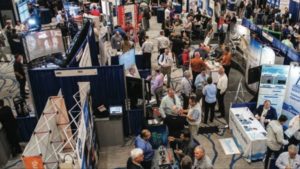

IMC-2018 Highlights

Fluke Accelix team members are having fun at IMC-2018. Stop by Booth 304 to meet the team and get firsthand product experience. Check out our slideshow below for event highlights. The show includes…

Visit Fluke at IMC 2018

The 33rd International Maintenance Conference (IMC 2018) takes place December 10-14 at the Hyatt Regency Coconut Point in Bonita Springs, Florida. Be sure to meet the Fluke Accelix team at Booth 304. You…

Accelerating the reliability journey

How a connected reliability framework makes a step change in IIoT adoption possible.