IIoT and Vibration Based Condition Monitoring—A False Dawn?

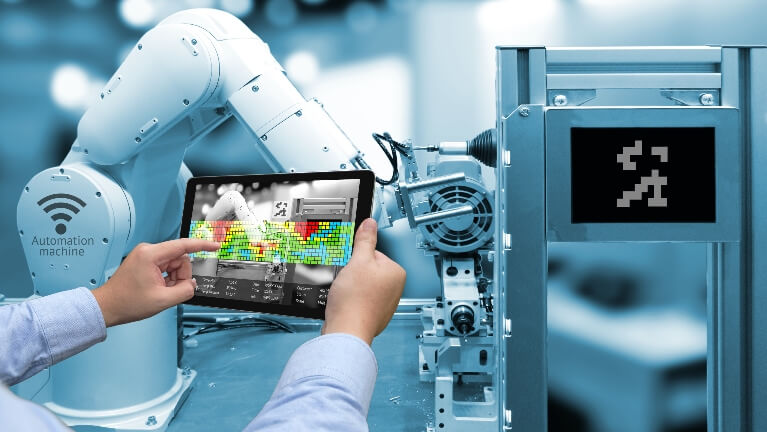

The use of Industrial Internet of Things technologies has the potential to radically transform the way organizations approach condition monitoring. There are many new entrants to the market touting their usage of low cost and low power sensing technologies coupled with Machine Learning and Artificial Intelligence techniques to provide scalable, cost-effective balance of plant condition…