Articles

Defect elimination programs change the culture by solving lots of little problems first

A defect elimination program targets the smallest, most irritating problems in a plant. It does so by giving everyone a stake in improving daily work life by eliminating errors and faults. In the process, a stronger continuous improvement culture takes hold, creating more widespread support for reliability initiatives at every scale. Michelle Ledet Henley, president…

Adding business value through data-driven maintenance

By Ankush Malhotra President at Fluke Reliability Every day, in manufacturing facilities worldwide, experienced and capable people are trying to second-guess the maintenance requirements of the machines that populate their plants. The reason is simple: They know that an effective maintenance program can increase their uptime, decrease maintenance costs, reduce unplanned outages, and extend the…

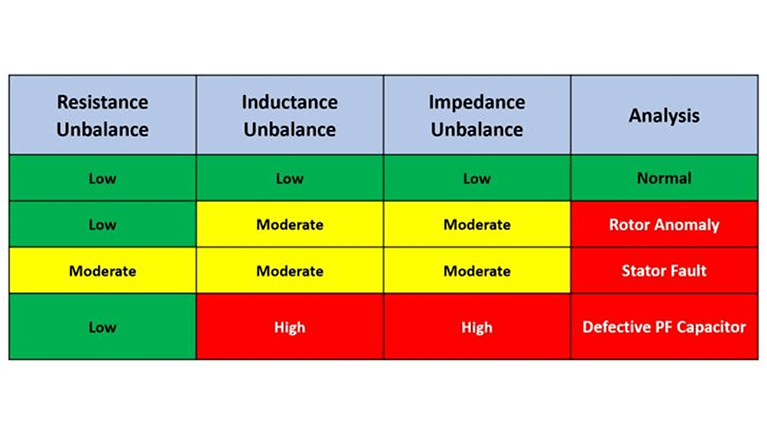

A look at the two principal motor testing methods: de-energized and energized

Every industrial facility has motors. They may range in horsepower, age, OEM, and criticality, but they’re still the most common asset facing maintenance and reliability (M&R) teams. According to the Electric Power Research Institute, improving motor maintenance can improve operational efficiency by up to 15%. In a webinar he gave for Fluke Reliability in February…

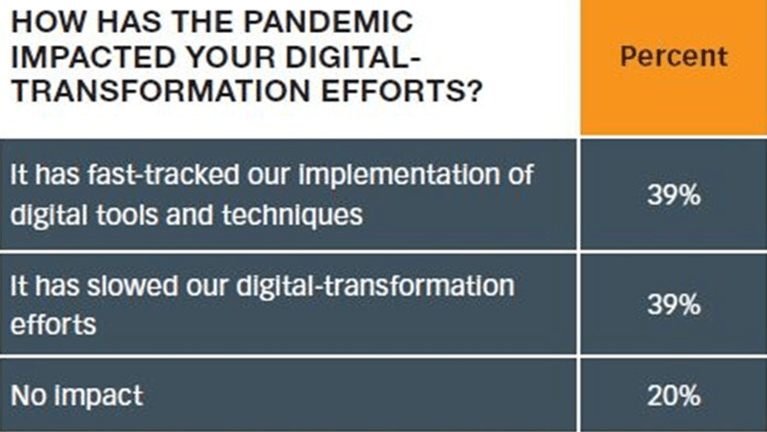

Manufacturing industry is primed to digitalize

By Ankush Malhotra At the start of 2021, I took part in a panel discussion with Keith Larson, Editor at Control magazine and Publisher at Putman Media. His team did some excellent research into the pace of manufacturing digitalization in 2020 compared to prior years. I’ve included links below to our webinar and the 2020…

Pandemic or not, digital transformation of maintenance workflows is moving forward

“We’re looking at new tools, new workflows, and continued higher use of mobile and remote devices. While route-based maintenance is not going away, we are seeing higher use of sensors and other online tools that give you the pulse of the assets and allow maintenance technicians to better prioritize their time. To become more proactive…

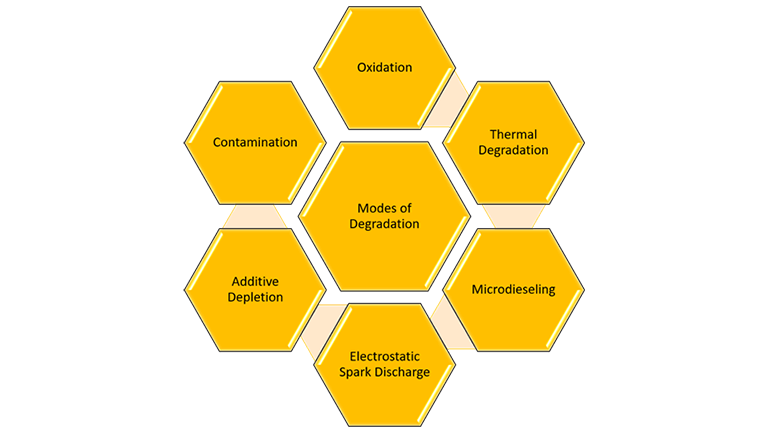

Breaking down lubricant degradation by failure mode for reliable oil analysis

To successfully integrate oil analysis into your machine reliability practices, you must first understand how lubricants degrade. That point was made exceedingly clear by lubricant expert Sanya Mathura in a January 2021 webinar for Fluke Reliability. Mathura, managing director of Trinidad-based Strategic Reliability Solutions, detailed the six ways lubricants degrade and offered advice on handling…

7 Benefits to help make the case for an Asset Criticality Assessment

Fluke Reliability provides a quick rundown on how to gain leadership buy-in for an Asset Criticality Assessment.

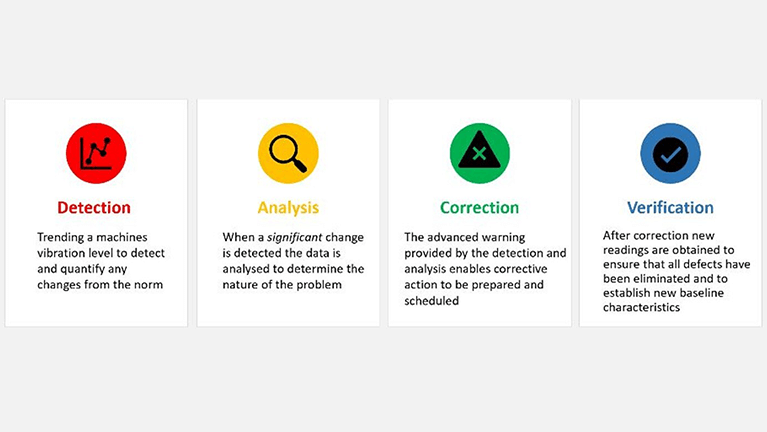

Industry expert Colin Pickett offers best practices for condition monitoring and vibration analysis

With more than 35 years of experience helping educate customers on the finer points of asset condition monitoring and vibration analysis, including 15 years as a Prüftechnik engineer, Colin Pickett has developed an authoritative list of best practices. Now a full-time consultant and trainer, Pickett shared his depth of knowledge at a November 2020 Fluke…

It’s 2021. How’s your IIoT program doing?

If you’ve been waiting until the time is right to begin focusing on your Industrial Internet of Things (IIoT) initiatives, you just might be waiting too long. The fact is that the concept of interconnected applications, equipment, and technology is more than just an abstraction. The IIoT market is forecast to grow to $110.6 billion…