Articles

University Housing Streamlines Work Order Management with CMMS

It can be challenging to keep a university housing system working properly with effective work order management and forecasting abilities of future maintenance requirements. One university housing office began searching for an efficient way to automate work order and asset management with a computerized maintenance management software (CMMS) system. The univeristy’s housing assets include five…

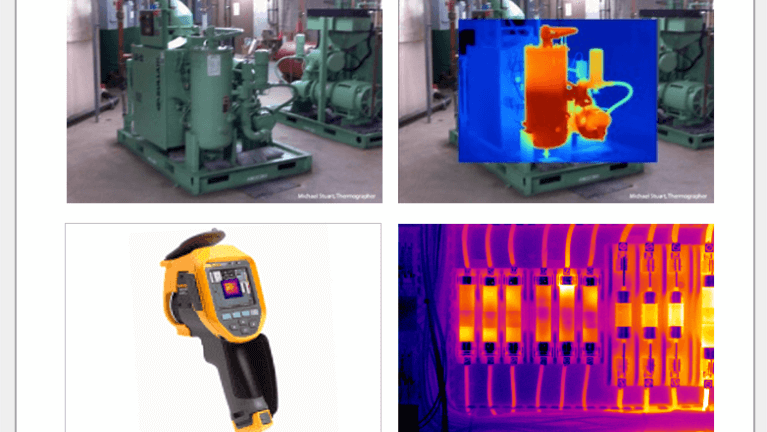

How to take condition-based maintenance to a higher level with thermography

Here’s a common scenario: Your maintenance team already uses thermography to inspect critical assets, either via an in-house person trained to use an infrared camera or via a service. Inspections are performed on a regular basis and when a change in asset operating temperature is detected compared to the previous inspection, a flag goes up…

Implementing organizational change requires accountability plus a long-term focus on behaviors

Why is it difficult to enact the changes that leaders want? It’s not a rhetorical question. For leaders and project managers everywhere, implementing the change they’ve ordered is frequently the most challenging part of the job. In his October 2020 webinar with Fluke Reliability, titled, “Actually implementing a change,” leadership expert Tom Moriarty identified two…

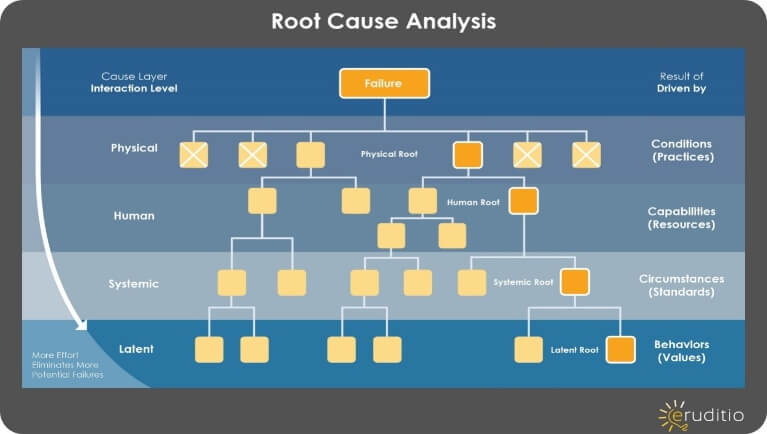

If reliability improvements elude you, look deeper into the ‘Tree of Unreliability’

What is causing your organization to struggle to get to its desired level of asset reliability? You’ve been using root cause analysis (RCA) and the Five Whys and addressing the problems you’ve found, but disruptions or unplanned downtime persist. Shon Isenhour, a veteran reliability engineering trainer and the founding partner at Eruditio, suggests pushing your…

See the latest innovations in reliability—from wherever you are!

Get ready to explore a wide range of cutting-edge topics to improve your reliability at the Xcelerate20 virtual conference November 17-19, 2020. This three-day event provides numerous opportunities to see firsthand (from your phone or computer) how the latest software, tools, and processes can help you fine-tune your 2021 maintenance plan. Get inspired by our…

Improving workplace safety may demand a culture change

Like a successful reliability program, an effective workplace safety initiative requires getting the entire team on board. Workplace safety issues only abate when everyone understands and actively supports a zero-incidents goal. The difference between improving safety (or reliability) or continuing to experience problems comes down to culture. Safety expert Chuck Pettinger of Fortive-owned Predictive Solutions…

Kickstarting condition-based maintenance with a Connected Reliability Assessment

Just like every facility is different, every maintenance operations team faces different challenges in reaching their next equipment reliability goal. One obstacle in particular is more common these days, however. With the current pressures facing plant operations, many teams would like to start using digitalized condition monitoring or connected sensors on the Industrial Internet of…

Using asset criticality to drive vibration monitoring applications

Adding vibration monitoring data to your eMaint CMMS can give you a better understanding of critical equipment health. But where do you start? First, identify the critical equipment you want to track. There are typically hundreds—if not thousands—of pieces of equipment that the maintenance team maintains, but some machines are more important to the company…

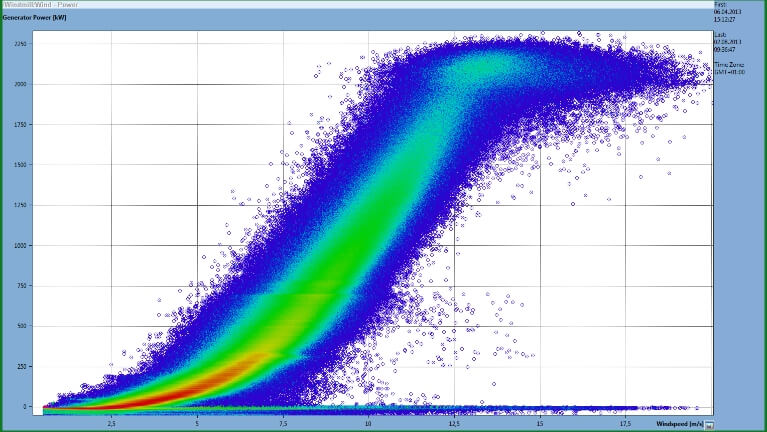

Increase condition monitoring success by utilizing process parameters

Deploying a condition monitoring program to better track asset health and performance can have the effect of narrowly focusing the team on one or a few types of data. Typically, maintenance and reliability professionals install a sensor such as an accelerometer on machines to measure vibration and relay that data to a vibration analyst to…