Articles

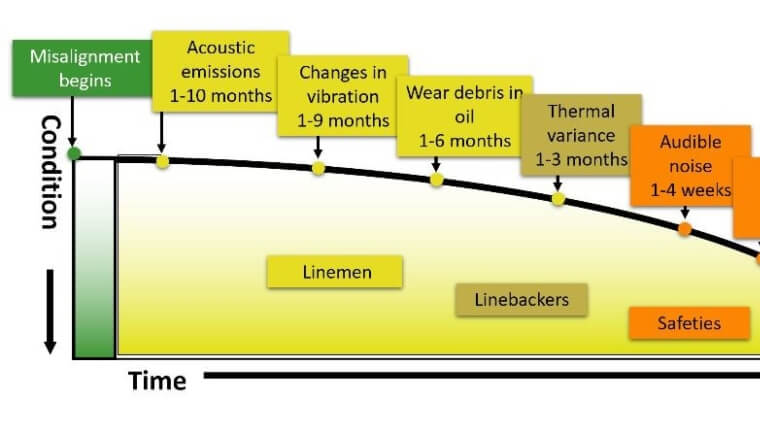

Using football strategies to strengthen your reliability engineering game

Improving how reliability engineers handle their machinery and other assets requires a strong “game plan,” says Mike Smith, senior consultant at Life Cycle Engineering. He likes to borrow from football coaching—specifically, the defensive coordinator’s role—for ways to do that. In the August 2020 webinar he presented for Fluke Reliability, “How to build a game plan…

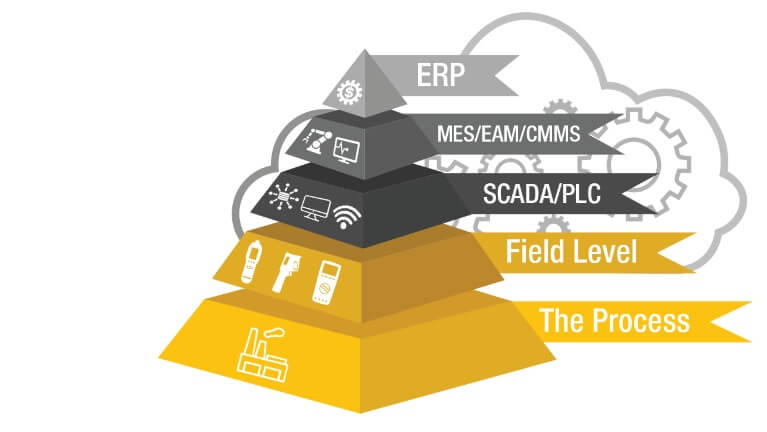

Top 5 Reasons Why Companies’ IIoT Initiatives Fail

By Brian Harrison According to a Fluke survey done in late 2019, some 50% of maintenance and reliability teams were actively planning Industrial Internet of Things (IIoT) initiatives. This, of course, was before the massive change brought upon us all by the spread of the coronavirus. Still, at the time, more than half of those…

What your M&R peers are planning to address in their pandemic recovery

At a time like this, when normal is abnormal and abnormal has become business as usual, it can be useful to find out how your peers are approaching their maintenance strategies. That’s why we at Fluke worked with Plant Services this spring to survey more than 200 maintenance and reliability professionals to assess how the…

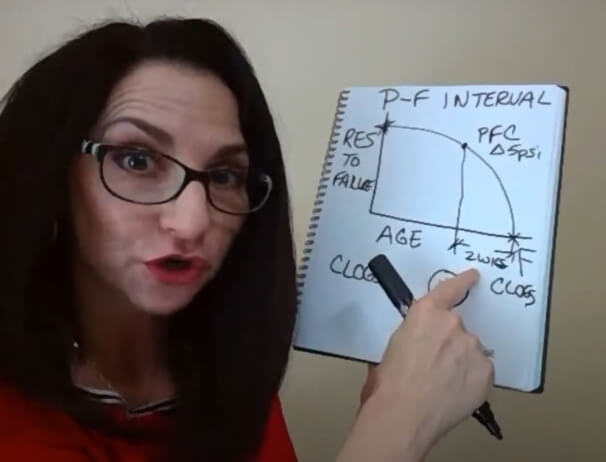

Gain control of your machines by putting more emphasis on reliability fundamentals

Nancy Regan, an internationally recognized maintenance and reliability trainer, puts it this way: “Either you successfully control your equipment, or you let it control you.” In a July 2020 webinar for Fluke Reliability, Regan, a Reliability Centered Maintenance (RCM) expert and founder of RCMTrainingOnline.com, examined the core question of “Are you letting your machines control…

Maintenance automation and the P-F Curve – cocktail for the pandemic and beyond

The pandemic that has upended normalcy in 2020 is fueling urgency among maintenance leaders for system improvements previously viewed as “future considerations.” The ability to monitor asset health remotely, for example, has gone from a “want” to a “need”—something essential to stay productive in the near term and competitive over the long run. Around 82%…

How CleanMaint helps you manage sanitization practices and inventory

Returning to work will mean different things for different companies and industries, but one thing everyone will likely require: Stronger, more detailed sanitization practices. Many businesses worldwide have already added enhanced deep-cleaning routines, either temporarily or permanently. To keep employees safe, shared tools and surfaces — and common areas, such as entrances and exits, clock-in…

Virginia first state to enact workplace safety rules after COVID-19

On July 27, 2020, Virginia became the first state in the U.S. to introduce workplace safety rules related to COVID-19. “These first-in-the-nation safety rules will protect Virginia workers by mandating appropriate personal protective equipment, sanitation, social distancing, infectious disease preparedness, and response plans, record keeping, training, and hazard communications in workplaces across the Commonwealth,” Gov….

Achieve industrial safety and reliability: FRS on the Industrial Talk podcast

Mike Mills, CRL, Senior Sales Engineer at Fluke Reliability, recently appeared on the Industrial Talk Podcast with Scott MacKenzie. Mills talked about industrial safety and reliability through a focus on continuity, agility, and repeatability. One of the many impacts of COVID-19 has been staffing—many organizations have not been able to have as many people on…

How to break habits and implement pandemic-related changes at the plant

“Virus-driven decision making.” Dr. Klaus Blache, Director of the Reliability and Maintainability Center (RMC) at the University of Tennessee, used this phrase to begin his June 2020 webinar, “How to lead and maintain reliability in a crisis.” “Many things have changed, and many have not in these challenging times of virus-driven decision making. (But) as…