Articles

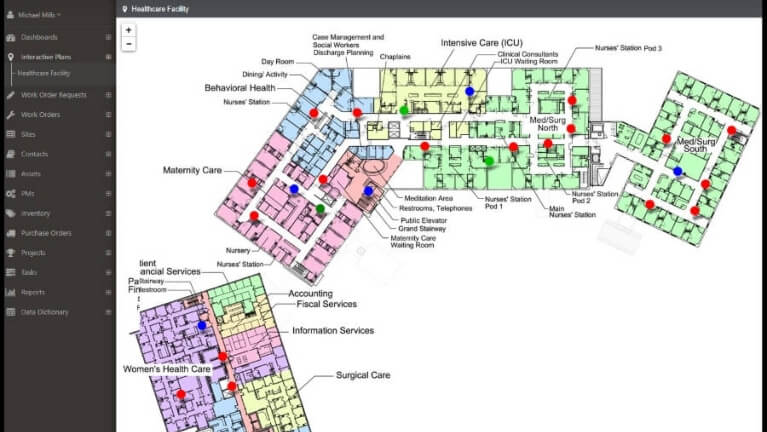

Boost Workplace Safety and Compliance with eMaint CMMS Software

Enhancing your organization’s workplace safety program and adjusting both your onsite and offsite operational processes immediately, rather than post-COVID-19, will pay off in the future. Most likely, you’ll soon need to meet additional compliance regulations and, although there are no new mandates yet, many manufacturing and other industrial sectors expect them to come. Meanwhile, you…

Sidetracked from condition monitoring goals? Plan a pilot program

Even if your maintenance and reliability team must work at home during COVID-19, progress on your reliability journey does not have to stop. You can develop a pilot program to roll out condition monitoring when plants are allowed to reopen under new guidelines. A pilot program enables you to test feasibility, refine as necessary, demonstrate…

Q&A on early learnings from the pandemic

Ramesh Gulati, Asset Management and Reliability Specialist at Jacobs Asset Management Group, discussed in a recent webinar some of the early lessons learned and the impact they will have on maintenance and reliability teams going forward. During the webinar, Ramesh held a Q&A session. What would be the major impediments to restructure the work dynamic in…

Inventory management during the pandemic: strategies for maintenance and supply chain pros

Traditional supply chain management practices have emphasized stringent, just-in-time inventory and cost controls. With the current disruptions to manufacturing and shipping logistics, much has changed. Continuity has become the No. 1 priority. In other words, with supply chains now less predictable and a longer wait time for getting parts in-house, you must do whatever you…

The A-B-Cs of the P-F curve

We’re focusing on the P-F curve again in this blog post, as we did in a previous blog post, because of its application to PRUFTECHNIK machinery alignment and condition-monitoring technologies. We’ll also introduce you to the term “capacity assurance.” Used effectively, PRUFTECHNIK technologies contribute to proactive maintenance strategies that work early in the P-F curve…

Keep employees’ skills sharp with Fluke Reliability webinars and training

When the more than 100 attendees at a Fluke Reliability Best Practice Webinar in April 2020 were asked, “How are your organization’s maintenance and reliability teams currently working,” nearly 70 percent said at least some team members were working remotely (versus onsite at their plant). More than 33 percent said most of their M&R employees…

Step up to improve your data quality and watch the confidence in your operations grow

A recent study published by MIT Review suggests that the manufacturing sector is making life harder than it needs to be. Manufacturing ranks among the bottom five sectors to be using digital technologies to enable employees to work better. Manufacturing has digitalized many of its systems, but it hasn’t managed to achieve the transformative results…

Remote monitoring and other benefits of the cloud

Amid an overwhelming threat to physical and economic health, organizations are finding new ways to maintain business continuity. That is especially true for industrial maintenance and reliability groups that have already adopted new cloud-based technologies for asset monitoring, maintenance tracking, workflow management, and reporting. Many are in decent shape to maintain their operations within the…

Five things to do when no one can be in the plant

With many companies ordered to shut down and people ordered to stay in their homes to mitigate the spread of COVID-19, organizations and teams have had to adapt—and suddenly. If your maintenance team cannot work in your plant, what should you do? How can you leverage this unplanned downtime? We went to some Fluke Reliability…