Past Webinars

The Importance of Precision Shaft Alignment

Discussing the real return on investment of properly aligning rotating equipment. As there is a renewed focus on reliability and vibration monitoring, I focus on a root cause. An often-quoted comment is “…why…

Diagnostic Engine: Empowering Data Analytics

Ensuring the success of your connected reliability program is essential for the management team. Many companies today are facing vibration data overload, where the excessive amount of vibration data exceeds analytic capacity in…

How to Leverage AI to Help Define Spare Parts Criticality Methodology

Reliability and Operations teams have always struggled with a repeatable process for defining criticality for maintenance spare parts management. It is often too easy to make everything critical and often entails a binary…

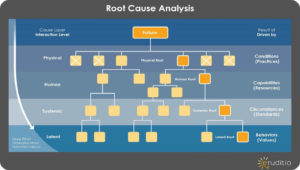

Root Cause Analysis

What is the most effective method? Does your company perform Root Cause Analysis (RCA) or just failure analysis? What distinguishes these tools and when are they appropriate? Does your company have a written…

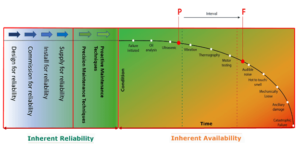

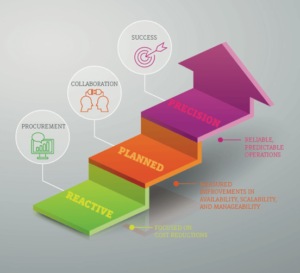

Predictive Maintenance, the Baby Steps to Big Results

During this session we will review impact (safety moment), maintenance strategies, sensors, IOT gateways, monitoring options, baby steps, and the “Why?”. Speaker:Gary Stevens CRL, FMP – Director of Engineering and Maintenance at C&W…

Impact of Power Quality Events on Motor Driven Systems

Over their operating lives, motors and other equipment encounter various power quality events, including voltage unbalance, single-phasing, and momentary interruptions. Having familiarity with power quality events and how they impact facility operations is…