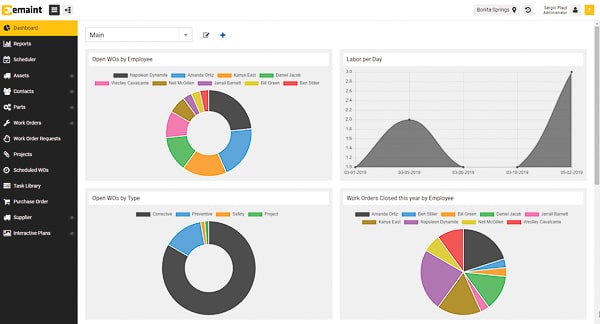

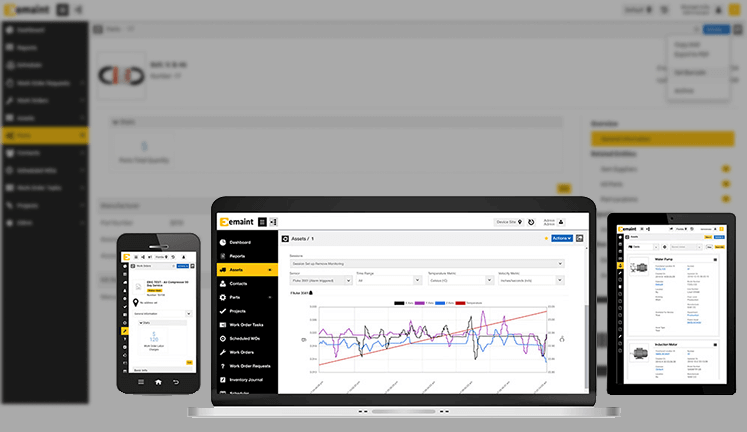

eMaint Connect Webinar Q3: What’s New and What’s Coming with eMaint?

This quarterly session is your exclusive opportunity to stay informed, inspired, and ahead of the curve with everything happening at eMaint. Our presenters are Michael Mills — Technical Sales Manager and Navin Kulkarni – Director of Product Management. What to Expect: Why You Should Attend: Presenters:Michael Mills – Technical Sales Manager Navin Kulkarni – Director…