Preventive Maintenance Articles

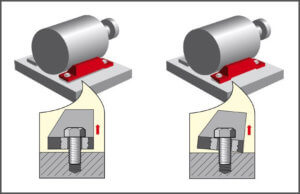

Give Soft Foot the Boot – Discover the Hard Facts

In this session, we explored the often-overlooked issue of soft foot—an alignment problem that can cause excessive wear, inefficiencies, and costly equipment failures. Our experts covered how to identify soft foot, why it…

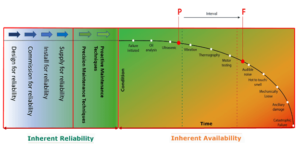

“Walking the Talk” of Asset Management

In capital-intensive industries, effective Asset Management is critical to profitability, ensuring that essential production assets are maintained at the lowest cost while maximizing availability and reliability. Asset Management encompasses three key elements: Work…

Adaptive Alignment – Solving Every Shaft Alignment Challenge

What if laser alignment systems could automatically adapt to different assets, simple-to-complex alignment challenges, and any user’s skills and experience? Such adaptability is the hallmark of a new generation of laser alignment technology….

The Importance of Precision Shaft Alignment

Discussing the real return on investment of properly aligning rotating equipment. As there is a renewed focus on reliability and vibration monitoring, I focus on a root cause. An often-quoted comment is “…why…

Diagnostic Engine: Empowering Data Analytics

Ensuring the success of your connected reliability program is essential for the management team. Many companies today are facing vibration data overload, where the excessive amount of vibration data exceeds analytic capacity in…

How to Leverage AI to Help Define Spare Parts Criticality Methodology

Reliability and Operations teams have always struggled with a repeatable process for defining criticality for maintenance spare parts management. It is often too easy to make everything critical and often entails a binary…

Confidence Rating – Trusting Your Repair Action Recommendations

This webinar will discuss automation in vibration analysis and how to obtain a Confidence Rating in the results to understand trust and best manage the next steps. Speaker:Michael DeMaria, Product Manager for Azima…

Understanding Failure Codes in CMMS

In this Best Practices Webinar, Remco Jonker teaches us about failure codes, cause codes and remedy codes.

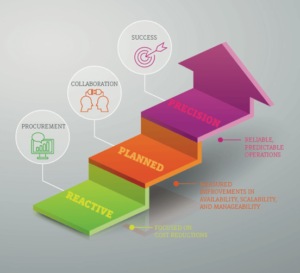

How machine alignment impacts maintenance strategies

Much of the work tied to machine alignment is standardized. But what happens after the alignment? There aren’t formal standards for what comes next, yet the strategies you adopt after alignment can help…